Quilting is a beloved tradition, blending creativity, skill, and heritage across generations. Yet, for many enthusiasts, the expense of quilting fabric can present a hurdle. why is quilting fabric so expensive?

In this exploration, we will dissect the factors driving the cost of quilting fabric and strategies to lower costs.

What Is Quilting Fabric?

Quilting fabric refers to any material used in making quilts, typically featuring a simple over-under weave pattern. This pattern involves sewing multiple layers of fabric together, creating a thicker, padded texture commonly seen on bed covers. So, why is quilting fabric so expensive?

Why Is Quilting Fabric So Expensive?

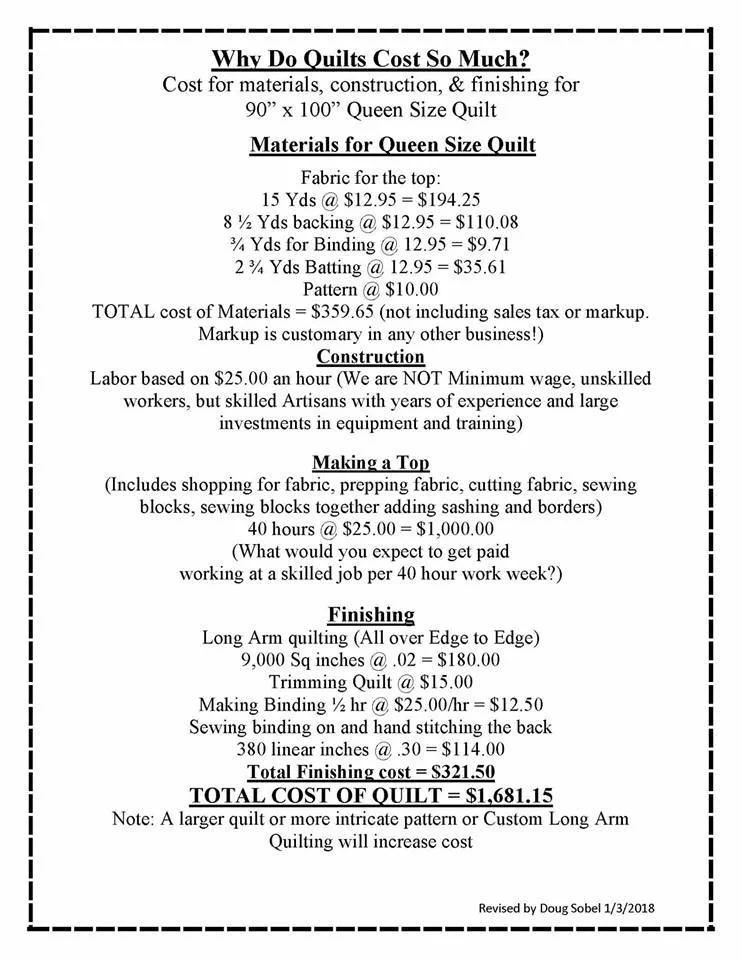

Why is quilting fabric so expensive? In 2018, photographer and quilter Doug Sobel created a meme that circulated on Facebook, addressing the question of why quilts carry a high price. I find it particularly enlightening for those unacquainted with handmade goods.

Sobel highlights longarming as the quilting method, signifying quicker completion compared to machine quilting. Consequently, opting for machine quilting prolongs the process, leading to a higher price.

What factors affect prices?

1. Labor-Intensive Production Process:

Quilts are labor-intensive creations, passed down through generations. From selecting fabrics to stitching intricate patterns, every step demands precision and dedication. Whether hand-sewn or machine-quilted, each quilt is a testament to the artisan’s skill, resulting in a cherished heirloom renowned for its warmth and beauty.

2. Complicated Quilt-Making Steps:

Quilting fabrics can be expensive due to the complex production process.

Key points include:

Design and planning: Deciding on quilt size, design, color scheme, and choosing blocks, patterns, or motifs. Selecting high-quality fabrics for top, batting, and backing considering color coordination and texture.

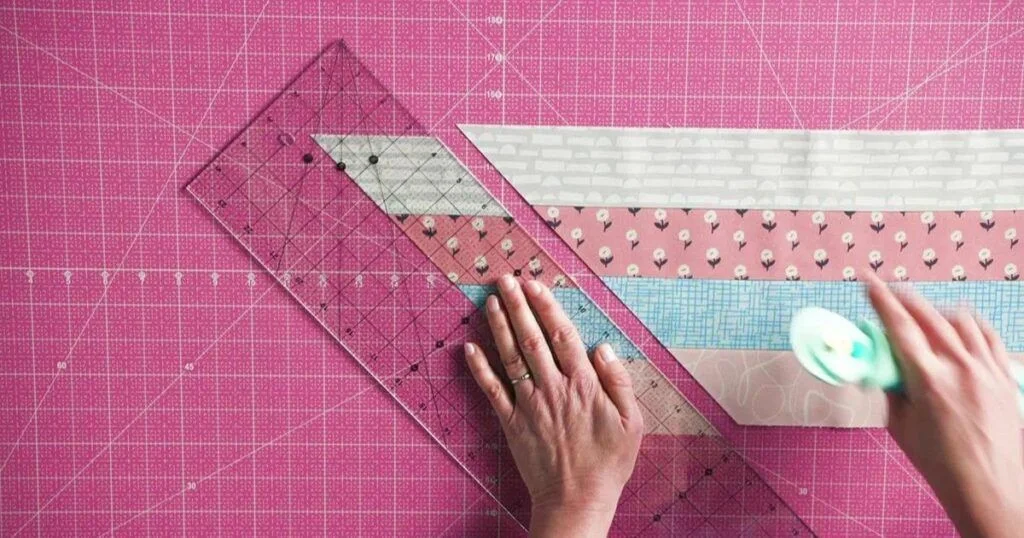

Cutting fabric: Using quilting tools to cut pieces accurately.

Piecing: Sewing fabric pieces to create blocks with proper seam allowances and alignment.

Block assembly: Arranging and sewing blocks to form the quilt top while ensuring pattern continuity.

Adding borders: Attaching borders for visual interest and structure.

Layering: Creating a quilt “sandwich” with top, batting, and backing, smoothing wrinkles and aligning layers.

Quilting: Stitching through all layers for texture by hand or machine following a design.

Binding: Adding binding strips around edges with mitered corners.

Finishing touches: Trimming excess fabric, inspecting for imperfections, and optionally adding personalization.

3. Expensive Sewing Machines And Tools :

Quilting fabric often demands specialized sewing machines and tools, contributing to its overall cost. These machines, designed for precision and versatility, enable quilters to create intricate designs and stitch patterns with ease.

Additionally, a variety of tools such as rotary cutters, quilting rulers, and specialty needles are essential for accurate cutting and stitching. While these investments may seem expensive upfront, they are essential for achieving professional-quality results and enhancing the quilting experience.

4. Cost Of High-quality Quilting Material:

The cost of high-quality quilting materials, including fabrics, batting, backing, and binding, can vary depending on factors such as brand, fiber content, and intricacy of design.

Premium quilting fabrics are often made from 100% cotton or other natural fibers, offering superior durability, color retention, and ease of handling.

Batting, the inner layer of a quilt, may come in various thicknesses and compositions, such as cotton, polyester, or wool, each with its own price point.

Backing fabric, which provides stability and structure to the quilt, is typically chosen to complement the quilt top and can range from basic cotton to specialty fabrics like minky or flannel.

Lastly, binding fabric, used to finish the edges of the quilt, can be purchased in coordinating or contrasting colors and textures to add visual interest. While high-quality quilting materials may come at a higher initial cost, they contribute to the overall beauty, durability, and value of the finished quilt.

5. complex nursing process

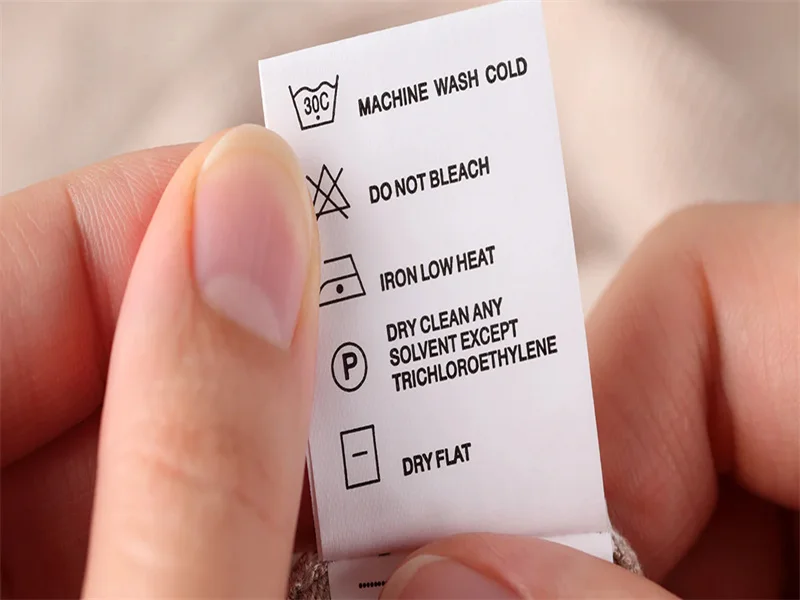

Another reason why quilting fabrics are expensive is the intricate care and maintenance process. Quilts made with these fabrics require special attention to ensure their longevity and beauty.

Regular cleaning must be done carefully to avoid damage to the delicate fabric and stitching. Hand washing or using a gentle cycle on the washing machine is often recommended, along with mild detergents that won’t harm the fabric. After washing, the quilt needs to be laid flat to dry to prevent stretching or distortion.

Storage is also crucial. Quilts should be kept in a clean, dry place away from direct sunlight and moisture to prevent fading and mildew. Additionally, periodic airing out is necessary to keep the quilt fresh. The time and effort required for proper care and maintenance add to the overall cost of quilting fabrics.

Circulation cost

Why Is Quilting Fabric Priced So High?There are also some additional costs incurred during the circulation of products, mainly in the following aspects:

1. Quilt sellers need to cover costs and ensure profitability.

2. A fair pricing formula includes labor hours, minimum wage, and additional expenses like marketing and shipping.

3. Selling through retail stores poses challenges due to wholesale pricing dynamics. Alternatives like online platforms and craft shows offer different avenues for selling quilts.

Tips To Lower Quilting Fabric Costs

1. Streamlining Production Processes

Implement efficient cutting and sewing techniques to minimize material waste and reduce labor time.

Utilize batch production methods and optimize workflow to increase productivity and minimize downtime between tasks.

2. Sourcing Affordable Materials

Explore bulk discounts and wholesale options from fabric suppliers to secure lower prices per yard of fabric. Incorporate recycled or upcycled fabrics into quilt designs to reduce material expenses while promoting sustainability.

3. Leveraging Technology And Automation

Invest in cost-effective sewing equipment, such as computerized quilting machines or rotary cutters, to improve efficiency and accuracy in the quilting process. Utilize digital marketing tools, such as social media platforms or email newsletters, to promote quilts and reach a wider audience, reducing the need for costly traditional advertising methods.

By implementing these strategies, quilt makers can effectively reduce production costs while maintaining quality and maximizing profitability.

Conclusion

Are you tired of feeling puzzled by the high price tags on quilting fabric? It’s time to uncover the truth behind the cost and take action to make informed decisions.

Join us in delving into the intricate world of quilting fabric economics. Together, let’s explore the quality, intricacy, and labor that go into crafting each yard of fabric. By understanding the factors driving the prices up, we can advocate for fair pricing and support the artisans and businesses behind this beloved craft.

Spread awareness and educate fellow enthusiasts about the true value of quilting fabric. Together, we can foster a community that values craftsmanship, respects fair wages, and celebrates the artistry of quilting. Take a stand and be part of the movement to demystify the cost of quilting fabric today!