In the world of textiles, nylon fabric has carved out a significant niche for itself. Its widespread use in various applications, from sportswear to parachutes, has made it a household name. But have you ever stopped to wonder what nylon fabric is made of? In this blog post, we’ll delve deep into the composition of nylon, exploring its raw materials, manufacturing process, and the unique properties that make it so versatile. So, let’s embark on this journey to demystify the components of nylon fabric.

What is Nylon Fabric

Nylon is a synthetic polymer, which means it’s made from man-made materials through chemical processes. It was the world’s first synthetic fiber, developed by Wallace Carothers at DuPont in the 1930s. This groundbreaking invention revolutionized the textile industry, offering a durable, lightweight, and versatile alternative to natural fibers.

What is Nylon Fabric Made Of? A Comprehensive Guide

Nylon Fabric is a synthetic polymer, a creation born from human ingenuity and scientific innovation. Developed in the 1930s by Wallace Carothers at DuPont, it was a game-changer in the textile industry, offering properties that natural fibers couldn’t match. At its core, Nylon Fabric is composed of repeating units called monomers, which are linked together through a process known as polymerization.

The Chemical Building Blocks

The two most common types of Nylon Fabric, nylon 6 and nylon 6,6, have distinct chemical structures. For Nylon Fabric made from nylon 6, the monomer is caprolactam. When this monomer undergoes polymerization, it forms long chains, creating the foundation of the nylon 6 polymer. In the case of nylon 6,6-based Nylon Fabric, the monomers are adipic acid and hexamethylenediamine. These two monomers react via a condensation polymerization reaction, where a water molecule is removed for each bond formed, resulting in the formation of the nylon 6,6 polymer chain. Understanding these chemical building blocks is key to answering the question: What is Nylon Fabric made of?

Raw Materials That Shape Nylon Fabric

The journey of Nylon Fabric begins with carefully selected raw materials, each playing a crucial role in determining its final properties.

Petroleum: The Primary Resource

We find that most Nylon Fabric is derived from petrochemicals. Petroleum, a non-renewable fossil fuel, serves as the main source for producing the monomers used in nylon synthesis. Through a complex series of refining and chemical processes, petroleum is transformed into the essential chemicals needed for Nylon Fabric production. For instance, benzene, a compound obtained from petroleum, is a vital intermediate in the production of adipic acid, one of the monomers for nylon 6,6-based Nylon Fabric.

Other Essential Chemical Precursors

In addition to petroleum-based chemicals, other substances are involved in creating Nylon Fabric. For Nylon Fabric made from nylon 6, the starting material caprolactam can be produced from cyclohexanone, which is derived from phenol. Phenol itself can be sourced from coal tar or synthesized from benzene. Hexamethylenediamine, the other monomer for nylon 6,6-based Nylon Fabric, is produced by reacting adiponitrile with hydrogen, where adiponitrile can be synthesized from butadiene, another petrochemical product. These raw materials work in harmony to bring Nylon Fabric to life.

The Manufacturing Process of Nylon Fabric

The transformation from raw materials to the Nylon Fabric we know involves several intricate steps, each contributing to its unique characteristics.

Polymerization: The Formation of the Polymer

Polymerization is the crucial step in creating the nylon polymer that makes up Nylon Fabric. In the case of nylon 6-based Nylon Fabric, caprolactam is heated in the presence of a catalyst, causing the molecules to break open and link together, forming long chains of the nylon 6 polymer. For nylon 6,6-based Nylon Fabric, adipic acid and hexamethylenediamine are dissolved in water and heated under pressure. The reaction between these two monomers results in the formation of the nylon 6,6 polymer, laying the groundwork for the fabric.

Extrusion: Shaping the Fibers

Once the nylon polymer is formed, it’s time to shape it into fibers through a process called extrusion. We force the molten nylon polymer through tiny holes in a spinneret, a metal plate with numerous small openings. As the polymer passes through, it solidifies into fine filaments. The size of the holes in the spinneret determines the diameter of the filaments, which is essential for the final properties of the Nylon Fabric.

Drawing: Enhancing Strength and Durability

After extrusion, the nylon filaments are typically drawn. Drawing involves stretching the filaments to align the polymer chains in the same direction, enhancing the strength and durability of the fibers. The filaments are passed through a series of rollers that rotate at different speeds, gradually stretching them to the desired length, making the Nylon Fabric more resilient.

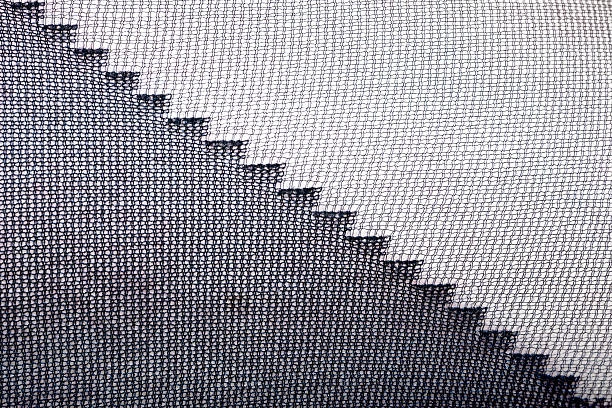

Weaving or Knitting: Creating the Fabric

Finally, the drawn nylon filaments are either woven or knitted to create the Nylon Fabric. In weaving, the filaments are interlaced at right angles to form a fabric structure, resulting in different weave patterns like plain weave, twill weave, or satin weave. Knitting, on the other hand, involves forming loops of the filaments and interlocking them, often resulting in a more stretchy Nylon Fabric.

Properties Influenced by Nylon Fabric‘s Composition

The unique composition of Nylon Fabric endows it with several remarkable properties that make it suitable for a wide range of applications.

Strength and Durability

The long, linear polymer chains in Nylon Fabric are held together by strong intermolecular forces, giving it excellent strength and durability. Nylon Fabric fibers can withstand significant stress without breaking, making it an ideal choice for applications where strength matters, such as ropes, seat belts, and industrial fabrics.

Lightweight

Despite its strength, Nylon Fabric is lightweight. Its synthetic nature allows for the creation of fibers that are much lighter than many natural fibers, like cotton or wool. This makes Nylon Fabric a popular option for applications where minimizing weight is crucial, such as outdoor gear and sportswear.

Moisture Resistance

Nylon Fabric has a certain degree of moisture resistance. While not completely waterproof, it doesn’t absorb water as readily as natural fibers. Its chemical structure repels water to some extent, which helps keep the fabric dry and comfortable, especially beneficial in sportswear where it wicks away sweat.

Abrasion Resistance

The smooth surface and strong polymer structure of Nylon Fabric make it highly resistant to abrasion. It can endure rubbing, scraping, and other mechanical stress without showing signs of wear and tear, making it perfect for products that undergo rough handling, like backpacks, luggage, and upholstery.

FAQ about What Nylon Fabric is Made Of

What are the primary raw materials for Nylon Fabric?

The primary raw materials for Nylon Fabric are petrochemicals. For nylon 6-based Nylon Fabric, the monomer caprolactam often comes from petrochemical-based cyclohexanone. Nylon 6,6-based Nylon Fabric is made from adipic acid and hexamethylenediamine, both produced from petrochemical products like benzene and butadiene.

Is Nylon Fabric eco-friendly, considering its raw materials?

Nylon Fabric, being made from petrochemicals, is derived from non-renewable resources. Its production requires a significant amount of energy and can generate greenhouse gas emissions. However, we’re seeing efforts to develop more sustainable ways to produce Nylon Fabric, such as using bio-based feedstocks or recycling existing nylon products.

Can Nylon Fabric be recycled?

Yes, Nylon Fabric can be recycled. Recycling involves breaking down used nylon products into their basic components and then re-polymerizing them to create new Nylon Fabric. This helps reduce the demand for new petrochemical raw materials and minimizes waste. Recycled Nylon Fabric can be used to make various products, from new fabrics to carpet fibers.

Are there natural alternatives to Nylon Fabric?

There are several natural alternatives to Nylon Fabric. Cotton, for example, is a breathable and comfortable natural fiber, although it may not match Nylon Fabric’s strength and durability. Wool offers good insulation, and linen, made from the flax plant, is known for its breathability and absorbency. However, these natural fibers lack some of the unique properties that make Nylon Fabric so versatile.

How does the manufacturing process affect the quality of Nylon Fabric?

The manufacturing process has a profound impact on the quality of Nylon Fabric. The polymerization step determines the molecular structure of the nylon polymer, influencing its strength and other properties. The extrusion process controls the filament diameter and shape, and the drawing process aligns the polymer chains, enhancing the fabric’s strength. The weaving or knitting method also affects the fabric’s texture, drape, and stretch properties.

Does Nylon Fabric contain any harmful chemicals?

During the production of Nylon Fabric, various chemicals are used. But once the fabric is produced and processed, it’s generally considered safe for use. The finished Nylon Fabric doesn’t typically release harmful chemicals during normal use. However, it’s important to ensure that any treated or dyed Nylon Fabric products meet safety standards.

Can Nylon Fabric be dyed easily?

Nylon Fabric can be dyed relatively easily. Its chemical structure allows it to absorb dyes well, resulting in vibrant and long-lasting colors. Different types of dyes, such as acid dyes and disperse dyes, can be used to color Nylon Fabric, depending on the specific requirements of the dyeing process.

What is the difference between nylon 6 and nylon 6,6 in terms of Nylon Fabric composition?

Nylon Fabric made from nylon 6 is composed of a single monomer, caprolactam. When this monomer polymerizes, it forms the nylon 6 polymer chain. Nylon Fabric made from nylon 6,6, on the other hand, is made from two monomers – adipic acid and hexamethylenediamine. These two monomers react to form the nylon 6,6 polymer, giving the two types of Nylon Fabric slightly different properties, like melting point and strength.

How does the raw material source affect the cost of Nylon Fabric?

The cost of Nylon Fabric is closely tied to the cost of its raw materials. Since Nylon Fabric is mainly made from petrochemicals, fluctuations in the price of petroleum can significantly impact its cost. An increase in petroleum prices raises the cost of producing the monomers for nylon, which in turn drives up the cost of the finished Nylon Fabric. The cost of sourcing and processing other raw materials also affects the overall price.

Are there any health concerns associated with wearing Nylon Fabric?

For most people, wearing Nylon Fabric doesn’t pose significant health risks. It’s generally hypoallergenic. However, individuals with sensitive skin might experience irritation if the fabric doesn’t allow proper air circulation and traps sweat. Also, if the Nylon Fabric has been treated with certain chemicals like flame retardants, there could be potential health risks if these chemicals leach out. But overall, properly produced and treated Nylon Fabric is safe for daily use.

Discover the Diverse Applications of Nylon Fabric

Thanks to its unique composition and properties, Nylon Fabric has a wide range of applications. In sportswear, we see Nylon Fabric used in running shorts, athletic jerseys, and swimsuits, taking advantage of its moisture-wicking and lightweight features. Outdoor gear like backpacks and tents rely on Nylon Fabric’s strength and abrasion resistance.

In the fashion industry, Nylon Fabric is used to create modern and stylish looks. It can be blended with other fibers to add structure and durability to garments. Nylon Fabric is also commonly used in hosiery for its smooth finish. In industrial settings, Nylon Fabric is employed in conveyor belts, ropes, and many other products where its strength and durability are highly valued.

In conclusion, by delving into what Nylon Fabric is made of, we gain a deeper understanding of why it has become such an indispensable material in various aspects of our lives. From its chemical composition to its diverse applications, Nylon Fabric continues to prove its worth as a remarkable synthetic textile.