So, what is nylon fabric? You probably touch it every day—whether you’re wearing your favorite workout gear, zipping up a jacket, or crafting something new at home. Nylon fabric is a synthetic material known for its strength, stretch, and versatility.

When you ask, “What is nylon fabric?” think of a fabric that handles tough jobs, dries quickly, and feels light. Recent studies show nylon’s popularity keeps growing in sportswear, automotive interiors, and even high-tech smart textiles. Many DIY lovers like you choose nylon fabric for its creative potential. If you want quality and inspiration, F&A leads the way with innovative nylon fabrics for every project.

Key Takeaways

- Nylon fabric is a strong, stretchy, and lightweight synthetic material used in clothing, sports gear, and many industries.

- Different types of nylon serve various purposes, from soft sportswear to tough automotive parts, making nylon very versatile.

- Nylon fabric dries quickly, resists wear and wrinkles, and is easy to care for with simple washing and storage tips.

- While nylon lasts long and performs well, it comes from petroleum and can harm the environment if not used or recycled responsibly.

- Choosing recycled or eco-friendly nylon and caring for it properly helps reduce environmental impact and supports sustainable use.

What is Nylon Fabric?

Nylon Definition

When you ask, “What is nylon fabric?” you’re really asking about one of the most important materials in modern textiles. Nylon fabric is a man-made material created through chemical processes. Scientists first developed nylon in the 1930s by experimenting with synthetic polymers.

They wanted to make a fiber that was strong, stretchy, and easy to produce. Nylon is part of the polyamide family, which means it comes from repeating units linked by amide bonds. You get nylon fiber by combining petrochemicals like benzene in a lab, then spinning the result into long, smooth threads.

Nylon fabric made its big debut in 1940. In that first year, factories produced 1,300 tons of nylon textiles, and people bought 64 million pairs of nylon stockings. That’s a huge number!

The demand grew so fast that companies opened more plants just to keep up. This early success showed everyone that nylon fabric was not only synthetic but also incredibly durable and practical for everyday use.

Key Properties

You might wonder why nylon fabric stands out from other materials. Here are some of the key properties that make it so popular:

- Strength and Durability: Nylon textiles are famous for their toughness. You can stretch nylon fiber, and it will snap back to shape. That’s why it works so well in clothing, sports gear, and even industrial products.

- Lightweight Feel: Nylon fabric feels light and smooth against your skin. You can wear it all day without feeling weighed down.

- Elasticity: Nylon stretches easily and returns to its original shape. This makes it perfect for activewear and fitted clothes.

- Quick Drying: If you spill water on nylon, it dries much faster than cotton or wool. This property helps in outdoor gear and swimwear.

- Resistance to Wear: Nylon textiles resist abrasion, so they last longer even with heavy use.

- Versatility: You’ll find nylon in everything from jackets and backpacks to car parts and medical supplies. Market research shows that nylon’s strength, elasticity, and wear resistance make it a top choice for many industries. The automotive industry uses nylon for engine covers and radiator parts because it’s lightweight and stable at high temperatures. You’ll also see nylon in household items, sporting goods, and machinery parts.

Tip: If you want a fabric that can handle tough jobs and still look good, nylon fabric is a smart pick!

Types of Nylon Fabric

You have many options when it comes to types of nylon fabric. Each type has its own strengths and uses. Here’s a quick look at the most common types of nylon fabric you’ll find:

| Type | Main Features | Common Uses |

|---|---|---|

| Nylon 6 | Good elasticity, easy to dye | Apparel, carpets, industrial yarn |

| Nylon 66 | High strength, heat resistance | Automotive parts, outdoor gear |

| Nylon 11 & 12 | Flexible, chemical resistant | Tubing, medical devices |

| Microfiber Nylon | Ultra-fine, soft, lightweight | Lingerie, sportswear, linings |

You’ll see nylon 6 and nylon 66 most often in clothing and industrial products. Other types of nylon fabric, like nylon 11 and 12, work better for special uses such as medical tubing or parts that need to resist chemicals. Microfiber nylon feels extra soft and light, making it great for delicate clothing.

The market for nylon textiles keeps growing. In 2023, the global nylon market reached $1.29 billion, and experts expect it to hit $2.12 billion by 2031. That’s a 6.4% growth rate!

This growth comes from the many types of nylon fabric used in fishing nets, medical supplies, automotive parts, and more. Companies keep finding new ways to use nylon fiber, especially as they develop eco-friendly and recycled options.

So, when you think about what nylon fabric is, remember that it’s not just one thing. It’s a whole family of strong, flexible, and useful materials that show up in almost every part of your life.

How is Nylon Fabric Made?

If you’ve ever wondered, “How is nylon fabric made?” you’re about to find out. The journey from raw materials to the finished product is a fascinating mix of science and technology.

Raw Materials

Nylon fabric starts with petrochemicals. You need chemicals like cyclohexane, caprolactam, adipic acid, and hexamethylenediamine. These ingredients come from petroleum.

When you combine them, you get a synthetic polyamide. This means nylon fabric is not natural—it’s made in a lab using fossil fuels. The process begins with these building blocks, which are the foundation for all nylon materials.

Production Process

The real magic happens during nylon fabric production. First, you mix hexamethylenediamine and adipic acid to create nylon salt. You heat this salt until it melts. Then, you push the molten mixture through tiny holes called spinnerets. This forms long, thin fibers.

Next, you stretch these fibers to line up the molecules. This step makes the nylon strong and elastic. Factories use high temperatures and pressure to get the best results. Some companies even recycle nylon by breaking it down into its original chemicals, showing how flexible the process can be.

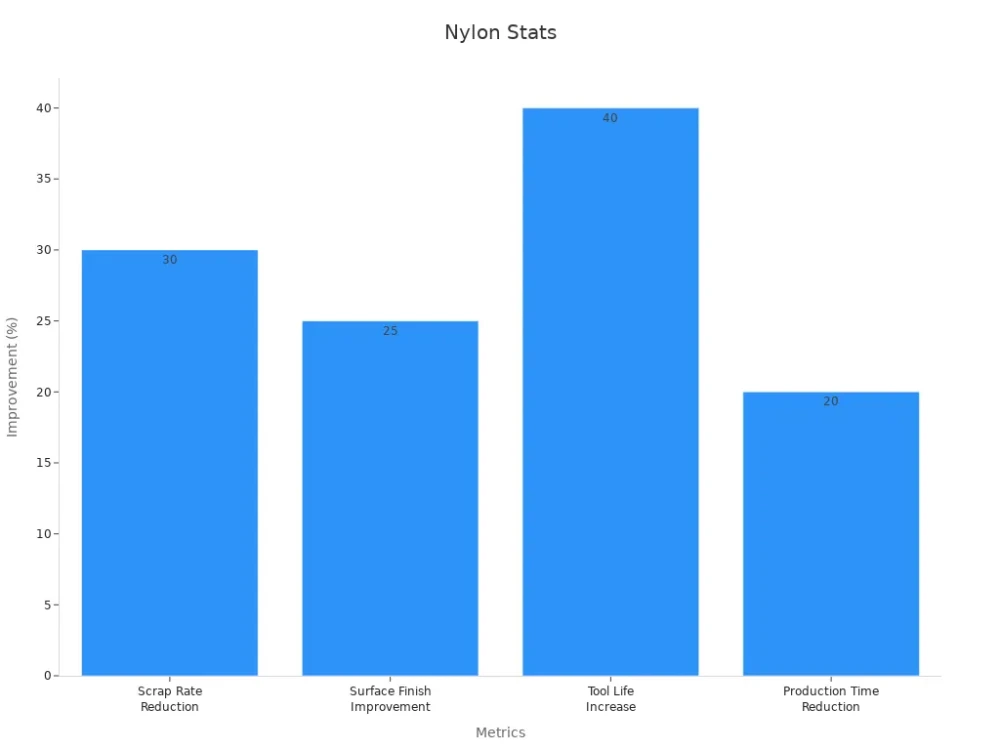

Modern manufacturers like F&A use advanced technology to make sure every yard of nylon fabric meets strict standards. Here’s a quick look at how new techniques improve quality:

| Metric | Improvement Achieved | Technique Used |

|---|---|---|

| Scrap Rate Reduction | 30% | Real-time monitoring and control |

| Surface Finish Improvement | 25% | Temperature management |

| Tool Life Increase | 40% | Tool wear inspection and adaptive feed control |

| Production Time Reduction | 20% | Batch processing and optimized parameters |

Finishing Techniques

Once you have the fibers, you’re not done yet. You need to treat and finish the nylon fabric to make it ready for use. Factories wash, dye, and sometimes coat the fabric to improve its look and feel.

F&A uses advanced pre-treatment steps like mercerizing and preshrinking. These steps help the fabric stay smooth, vibrant, and durable. Quality control teams inspect every batch to make sure you get the best nylon fabric for your projects.

Tip: High-quality finishing makes a big difference in how your nylon fabric looks and lasts!

How is Nylon Fabric Used?

Nylon fabric shows up in more places than you might expect. If you have ever wondered, “How is nylon fabric used?” you will find it in clothing, industry, and even your own home projects. Let’s break down the main ways you see nylon in action.

Apparel and Fashion

You probably wear nylon fabric every day. It is a favorite for sportswear, jackets, leggings, and even socks. Designers love nylon because it is strong, stretchy, and holds color well. Nylon textiles keep their shape and resist wrinkles, so your clothes look fresh longer.

You will also find nylon in swimwear, lingerie, and raincoats. The apparel segment holds a big share of the market because people want durable and fashionable clothing. Nylon blends with other fibers to create soft, comfortable fabrics that last.

Industrial Uses

Nylon is not just for clothes. Factories use nylon fabric in conveyor belts, filtration systems, and protective gear. You see nylon in automotive parts like seat belts, airbags, and upholstery. Its strength and resistance to wear make it perfect for tough jobs.

The industrial sector relies on nylon textiles for machinery parts, gears, and bearings. Market research shows that nylon’s versatility drives its use in many industries, from manufacturing to transportation. Nylon gear and technical applications keep growing as new innovations appear.

Home and DIY Projects

You can bring nylon fabric into your home in many ways. Upholstery, curtains, and bed linens often use nylon blends for durability and easy care. DIY lovers choose nylon for bags, accessories, and creative crafts. F&A stands out in the DIY fabric market by offering high-quality, customizable nylon textiles.

Their blend of tradition and innovation inspires crafters to create unique projects. Whether you sew, quilt, or decorate, nylon fabric gives you endless options for home décor and personal expression.

Tip: Try using nylon fabric for your next DIY project. You will love how easy it is to work with and how long it lasts!

Nylon Fabric Pros and Cons

Advantages

When you pick nylon fabric for your projects, you get a lot of benefits. This material stands out for its strength and long-lasting nature. You can stretch nylon, and it bounces right back. That’s why you see it in sportswear, backpacks, and outdoor gear.

Nylon fabric resists rubbing and tearing, so your items stay looking new even after heavy use. If you spill water, nylon dries quickly and keeps its shape. You don’t have to worry about mildew or mold, either. Nylon fabric also handles heat better than many other synthetic materials, making it a smart choice for tough jobs.

Here’s a quick comparison to help you see how nylon fabric stacks up against other common materials:

| Feature | Nylon Fabric | Polypropylene/Polyethylene |

|---|---|---|

| Strength | Very High | Moderate |

| Abrasion Resistance | Excellent | Lower |

| Heat Resistance | Up to 150°C | Up to 120°C or less |

| Cost | Higher at first | Lower |

| Durability | Superior | Moderate |

Even though nylon fabric may cost a bit more at first, you save money over time because it lasts longer and needs fewer repairs or replacements. That’s why so many people choose nylon for demanding uses.

Tip: If you want a fabric that can handle rough treatment and still look great, nylon fabric is a top pick!

Disadvantages

Nylon fabric isn’t perfect. You should know about a few trade-offs before you choose it for your next project. First, nylon comes from petroleum, so making it uses a lot of energy and relies on non-renewable resources. When you wash nylon fabric, it can shed tiny fibers called microplastics.

These microplastics end up in rivers and oceans, which is a big concern for the environment. Nylon fabric also does not break down in landfills, so it sticks around for a long time.

Some people notice that recycled nylon can be weaker than new nylon. This means you might see more pilling or less tear strength in certain recycled nylon fabrics.

If you care about the planet, you might want to look for nylon fabric made with eco-friendly methods or recycled content. Many brands now offer options that help reduce the impact on the environment.

Note: Washing nylon fabric less often and choosing recycled or bio-based options can help lower your environmental footprint.

Nylon Fabric and Sustainability

Environmental Impact

You might wonder what happens to nylon fabric after you use it. Nylon comes from petrochemicals, so making it uses a lot of energy. Factories release greenhouse gases during production. When you throw away nylon fabric, it does not break down quickly. It can sit in landfills for decades.

Washing nylon fabric also releases tiny fibers called microplastics. These microplastics travel through water systems and end up in rivers and oceans. Fish and other animals can eat these fibers, which can harm the environment.

If you care about the planet, you should know that nylon fabric has a bigger footprint than many natural fabrics.

Tip: Try to use nylon fabric for projects that need long-lasting strength. This way, you get the most out of each piece and reduce waste.

Eco-Friendly Practices

You have options if you want to make better choices with nylon fabric. Many companies now look for ways to lower their impact. F&A leads the way with eco-friendly production methods. They use advanced technology to reduce waste and save energy. Their team recycles water and uses less harmful chemicals during processing.

F&A also explores recycled nylon fabric, which comes from old fishing nets and other used materials. This helps keep waste out of landfills and oceans. Their quality control ensures that even recycled nylon fabric meets high standards. When you choose F&A, you support a brand that cares about both creativity and the environment.

Note: Look for recycled or sustainably made nylon fabric when you shop. Every small step helps protect the planet for future generations.

Nylon Fabric Care

Washing Tips

You want your nylon fabric to last and look great. Good news—taking care of nylon is easy! Always check the care label first. Most nylon fabric can go in the washing machine.

Use cold or lukewarm water. Hot water can damage the fibers and cause shrinking. Choose a gentle cycle. Add a mild detergent. Avoid bleach because it can weaken nylon and fade colors.

If you have stains, treat them right away. Dab the spot with a little soap and water. Do not rub too hard. For delicate nylon fabric, you might want to use a mesh laundry bag.

This helps keep your items safe from snags. After washing, avoid using the dryer if possible. Instead, hang your nylon fabric to air dry. High heat from dryers can cause nylon to lose its shape.

Tip: Nylon dries quickly, so you do not have to wait long before using your favorite items again!

Storage and Maintenance

Proper storage helps your nylon fabric stay fresh. Fold your nylon items neatly. Store them in a cool, dry place. Keep nylon away from direct sunlight. Sunlight can fade colors and weaken the fibers over time.

If you store nylon fabric for a long time, use breathable bags or containers. This prevents moisture buildup and keeps mildew away.

Check your nylon items now and then. Look for loose threads or small tears. Fix them early to stop bigger problems. If your nylon fabric gets wrinkled, use a low-heat iron or a steamer. Always place a cloth between the iron and the nylon to avoid melting.

| Care Step | What To Do | What To Avoid |

|---|---|---|

| Washing | Gentle cycle, cold water | Hot water, bleach |

| Drying | Air dry, avoid direct heat | High heat, tumble dry |

| Storage | Cool, dry, out of sunlight | Damp, sunny places |

Note: With a little care, your nylon fabric will stay strong, bright, and ready for your next project!

Conclusion

You now know what makes nylon fabric so useful in daily life. You get strength, flexibility, and easy care with nylon. You see it in clothing, gear, and creative projects.

When you choose nylon fabric, you balance durability with environmental impact. The future looks bright as brands like F&A lead with sustainable practices and new ideas. Here’s what’s shaping the next chapter for nylon:

- Recycled nylon from fishing nets and waste cuts emissions by about 50%.

- Certifications like GRS support ethical, sustainable production.

- The industry moves toward circular systems and zero-waste designs.

- Digital tools and collaboration drive transparency and innovation.

Think about both your needs and the planet when picking nylon products.

FAQ

What makes nylon fabric different from polyester?

Nylon feels softer and stretches more than polyester. You will notice nylon dries faster and resists abrasion better. Polyester holds color longer in sunlight. Both work well for activewear, but nylon gives you a smoother, silkier touch.

Can you sew nylon fabric at home?

Yes, you can sew nylon fabric with a regular sewing machine. Use a sharp needle and polyester thread. Set your machine to a lower speed. Nylon can slip, so pin or clip your pieces before sewing for best results.

Is nylon fabric waterproof?

Nylon itself is water-resistant, not fully waterproof. Many jackets and bags use coated nylon for extra protection. If you want full waterproofing, look for nylon with a special finish or add a spray-on water repellent.

Does nylon fabric shrink or wrinkle easily?

Nylon resists shrinking and wrinkling. You can wash it and hang it to dry without much fuss. If you see wrinkles, a quick steam or low-heat iron (with a cloth on top) smooths them out fast.