Corduroy, with its distinctive ridged texture and cozy feel, has been a staple in fashion and home decor for centuries. But have you ever stopped to wonder what exactly goes into making this unique fabric?

This post will delve into the origins and composition of corduroy, breaking down the materials and manufacturing techniques that give it its signature look and enduring appeal.

What is Corduroy Fabric?

Corduroy is a distinct and durable textile easily recognizable by its raised, parallel lines or “wales” on its surface. While often associated with a cozy, velvet-like feel, it’s typically made from cotton or a cotton blend, though other fibers like polyester, wool, or even spandex can be incorporated.

The unique ribbed texture is created through a specialized weaving process where extra sets of fibers are woven into the base fabric to form vertical floats, which are then cut and brushed to create the characteristic ridges.

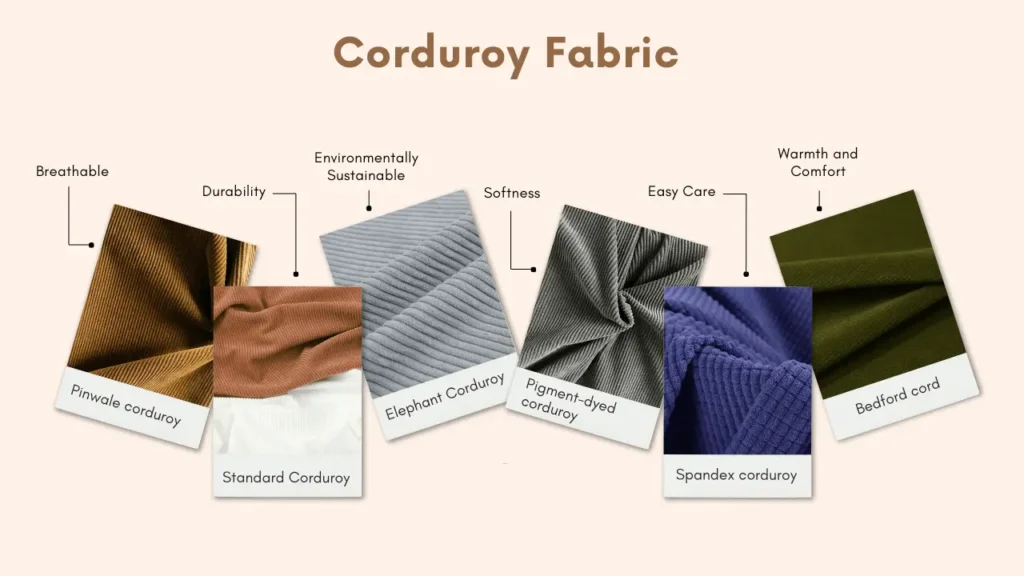

The width of these wales can vary significantly, from fine, closely packed “pinwale” or “needlecord” to wide, bold “elephant cord,” influencing both the fabric’s appearance and its typical use in garments and upholstery.

What is Corduroy Fabric Made Of?

Corduroy is a distinctive and durable fabric characterized by its unique parallel ridges, known as “wales.” While its appearance often suggests a thick, warm material, its composition can vary. The most common and classic form of corduroy is predominantly made from cotton, which provides a soft, breathable, and comfortable feel. However, to enhance certain properties like durability, stretch, or wrinkle resistance, other fibers are often blended in.

The specific fibers used in corduroy can include:

- Cotton: The most traditional and widely used fiber, offering softness, breathability, and a classic look.

- Polyester: Often blended with cotton to increase durability, resistance to wrinkles, and color retention.

- Wool: Less common, but sometimes used for added warmth, though the characteristic ridges may be less pronounced.

- Spandex (Elastane): A small percentage is often added to create “stretch corduroy,” providing enhanced flexibility and comfort, particularly for garments like pants.

The magic of corduroy’s texture lies in its specialized weaving process. It starts with a base fabric, typically a plain or twill weave, and then extra sets of weft (horizontal) yarns are woven in a way that they float over several warp (vertical) threads. These floating yarns are then cut and brushed to create the raised, plush ridges that define corduroy’s signature look and feel.

How to Make Corduroy Fabric?

Producing corduroy fabric is a multi-step process involving specialized techniques to create its signature texture. It begins with precise weaving, followed by careful cutting of threads, and finally, meticulous brushing and shearing. Each stage is crucial in transforming raw fibers into the durable, ridged fabric we know and love.

Step 1: The Weaving Process

The journey of creating corduroy fabric commences with a specialized and intricate weaving technique. Unlike the simpler over-under patterns of plain weaves, corduroy demands the deliberate incorporation of extra sets of weft yarns. These additional horizontal threads are not merely woven in; they are strategically floated over several warp (vertical) yarns, creating a series of intentional loops or raised sections on the fabric’s surface.

This precise manipulation during the weaving stage is fundamental, as it forms the very foundation upon which corduroy’s distinctive ridged texture will be built. Without these carefully formed loops, the subsequent steps would be impossible, and the fabric would lack the characteristic three-dimensional quality we associate with corduroy.

Step 2: The Cutting Stage

Following the completion of the weaving process, where the floating yarns have been meticulously integrated, the fabric moves to the next crucial phase: the precise cutting of these loops. This transformative step is executed using highly specialized machinery equipped with incredibly sharp, fine blades. These blades are designed to run precisely along the length of the fabric, targeting and slicing through the top of each individual loop.

This cutting action is what truly differentiates corduroy from other pile fabrics. It’s the moment the continuous loops are released, allowing them to spring open and form the recognizable, raised, parallel cords or “wales.” The consistency and precision of this cut are paramount, as they directly influence the uniformity and appearance of the final corduroy texture.

Step 3: The Brushing and Shearing Process

After the meticulous cutting of the loops, the newly formed wales are still in a somewhat unrefined state. To achieve corduroy’s signature soft, plush, and inviting feel, the fabric undergoes a vital finishing process: brushing. Large, rotating brushes gently yet thoroughly work across the fabric’s surface, lifting, separating, and untangling the newly cut fibers within each wale.

This brushing action not only enhances the fabric’s softness but also gives the wales their characteristic velvety texture. Following this, a precise shearing process might be applied. Shearing involves trimming any stray or uneven fibers from the surface of the wales, ensuring a consistent height and a perfectly uniform, refined appearance across the entire expanse of the corduroy fabric.

Properties of Corduroy Fabric?

Corduroy fabric boasts a range of desirable properties that contribute to its popularity and versatility. Its distinctive construction, featuring raised parallel ridges known as wales, gives it a unique aesthetic and feel. Key corduroy fabric characteristics include:

- Versatility: Corduroy is available in various weights, colors, and wale counts, making it adaptable for a wide range of applications, from sturdy outerwear to lighter shirts and decorative items.

- Durability: The dense weave and robust nature of corduroy, especially in wider wales, make it highly resistant to wear and tear, suitable for long-lasting garments and upholstery.

- Warmth: The raised pile traps air, providing excellent insulation and making corduroy a popular choice for cooler weather clothing.

- Softness: Despite its strength, the cut and brushed pile gives corduroy a soft, velvety hand feel, contributing to its comfort.

- Texture and Appearance: The prominent wales create a rich, tactile surface with a distinctive visual appeal. The width of the wales can vary, from fine “pinwale” to broad “elephant cord,” offering diverse textural options.

- Moisture Absorption: As it’s often made from cotton, corduroy can effectively absorb moisture, contributing to comfort.

Is Corduroy Fabric Sustainable?

The sustainability of corduroy fabric is a nuanced issue, largely depending on the materials used and the manufacturing processes involved. Traditionally, corduroy is made from cotton, which, while a natural fiber, can have a significant environmental footprint.

Conventional cotton farming often requires vast amounts of water, pesticides, and fertilizers, leading to concerns about water depletion, soil degradation, and chemical pollution. Furthermore, the dyeing and finishing processes for corduroy can be water and energy-intensive, and the use of certain chemical dyes can contribute to water pollution if not properly managed.

However, corduroy can be a more sustainable choice when produced with eco-conscious practices and materials. Organic cotton, grown without harmful pesticides and with more efficient water management, significantly reduces the environmental impact.

Similarly, corduroy made from recycled cotton or blends with sustainable fibers like hemp, TENCEL™, or recycled polyester offers a more environmentally friendly alternative. The inherent durability of corduroy also contributes to its sustainability; well-made corduroy garments can last for many years, reducing the need for frequent replacements and thereby decreasing overall consumption and textile waste.

Is Corduroy Natural or Synthetic?

Corduroy can be either natural or a blend of natural and synthetic fibers. Traditionally, it’s made from 100% cotton, a natural plant fiber.

However, modern corduroy often incorporates synthetic fibers like polyester or spandex to enhance its durability, stretch, or wrinkle resistance. This means you can find both purely natural and blended versions of corduroy.

Conclusion

Corduroy fabric, with its distinctive wales and soft texture, is a testament to clever textile engineering. From its base materials, predominantly cotton, to the intricate weaving, precise cutting, and final brushing and shearing processes, each step contributes to its unique aesthetic and durability.

Understanding how corduroy is made highlights its versatility and enduring appeal in fashion and home decor. Whether you’re drawn to its cozy comfort or its robust nature, corduroy remains a timeless choice.

For those looking to incorporate this classic fabric into their next project, consider exploring wholesale corduroy fabric options from reputable suppliers like Fanda Fabrics. Their range can help bring your designs to life.