Wool is a versatile and sustainable natural fiber that has been, then how is wool processed into fabric.

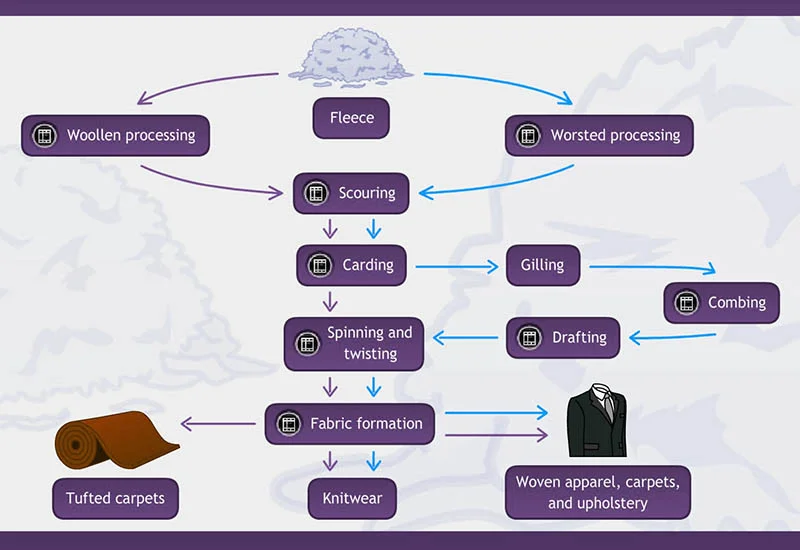

Wool undergoes many stages of processing to turn it into fabric, each crucial for achieving the desired texture and quality.

Understanding how wool is processed can give insight into the craftsmanship behind this timeless material.

What is Wool Fabric?

Wool fabric is a textile material made from the fibers of sheep’s fleece. It’s renowned for its warmth, durability, and natural elasticity.

The wool comes in various types and qualities depending on the breed of sheep, the processing method, and the desired end-use. It’s commonly used in clothing, blankets, carpets, and upholstery due to its excellent insulating properties and moisture-wicking abilities. Wool can be woven, knitted, or felted into different textures and patterns, making it a versatile and timeless choice in the world of textiles.

How is Wool Processed Into Fabric?

1. Shearing

Definition and Purpose of Shearing

Shearing is the process of removing wool from sheep, typically once a year. The primary purpose of shearing is to harvest wool for textile production, but it also benefits the animals by preventing overheating and promoting overall health.

Tools and Techniques

Modern shearing is usually performed using electric clippers, which are efficient and minimize stress for the sheep. Traditional methods involved hand shears, which required more time and skill. The technique used in shearing is crucial; it must be done carefully to avoid injuring the animal and to ensure the fleece remains in good condition.

Timing and Frequency of Shearing

Shearing is typically done in the spring, just before the hot weather sets in. This timing ensures that sheep do not overheat during the summer and that their wool grows back in time for winter. In some regions, sheep may be sheared twice a year, depending on the breed and local climate conditions.

Animal Welfare Considerations

Animal welfare is a critical aspect of shearing. Proper handling and care during shearing are essential to minimize stress and prevent injuries. Many wool producers follow strict guidelines and practices to ensure the humane treatment of their animals. These practices not only protect the sheep but also contribute to the quality of the wool produced.

2. Grading and Sorting

Criteria for Wool Grading

Once the wool is sheared, it undergoes a grading process to determine its quality. Grading criteria include fiber diameter (measured in microns), staple length, strength, color, and crimp. Finer wool, with a lower micron count, is typically softer and more valuable.

Sorting Process

Sorting, also known as classing, involves separating the wool into different categories based on its quality and characteristics. This process is usually done by skilled professionals who can quickly assess the wool’s attributes. Sorting ensures that the wool is grouped according to its intended use, whether for fine clothing, coarse carpets, or other products.

Quality Classifications

Wool is classified into various grades, each suitable for different applications. The highest quality wool, known as Merino, is prized for its softness and is often used in luxury garments. Other grades, such as crossbred or coarse wool, are used for more durable products like rugs and upholstery.

3. Scouring

Importance of Scouring

Scouring is the process of cleaning the wool to remove impurities such as dirt, grease, and vegetable matter. This step is crucial because it prepares the wool for further processing and ensures the quality of the final fabric.

Traditional vs. Modern Scouring Methods

Traditional scouring methods involved washing the wool in large vats of water, often with the addition of soap or other cleaning agents. Modern scouring uses more advanced techniques, including continuous flow systems and eco-friendly detergents, to improve efficiency and reduce environmental impact.

Environmental Impact of Scouring

Scouring has historically posed environmental challenges due to the large amounts of water and chemicals used. However, advances in technology and a growing emphasis on sustainability have led to the development of more environmentally friendly scouring methods. These include recycling water and using biodegradable cleaning agents to minimize the ecological footprint of wool processing.

4. Carding

Carding Process Overview

Carding is a mechanical process that disentangles, cleans, and intermixes the wool fibers to produce a continuous web or sliver suitable for further processing. This step is essential for aligning the fibers and removing any remaining impurities.

Carding Machines

Modern carding machines are equipped with a series of rotating drums covered in fine wire teeth. As the wool passes through these drums, the fibers are separated and aligned, creating a uniform web. The carded wool can then be processed into slivers or batts, depending on the intended use.

Role of Carding in Wool Processing

Carding plays a critical role in ensuring the quality and consistency of the final wool product. Proper carding enhances the wool’s loft and texture, making it easier to spin into high-quality yarns. Additionally, carding helps blend different types of wool fibers to achieve the desired characteristics in the finished fabric.

5. Combing

Purpose of Combing

Combing is an additional step that further refines the wool fibers by removing shorter fibers and any remaining impurities. This process aligns the fibers more thoroughly than carding, producing a smoother and stronger yarn.

Differences Between Carding and Combing

While carding is suitable for most wool processing applications, combing is typically used for high-quality wool that will be spun into fine yarns. Combed wool, also known as worsted wool, is preferred for producing smooth, lustrous fabrics with a crisp finish.

Machinery Used in Combing

Combing machines, or combers, use a series of fine-toothed combs to separate and align the wool fibers. The combed fibers, known as tops, are then drawn into a continuous

6. Spinning

History of Spinning

Spinning is one of the oldest textile arts, with evidence of hand spinning dating back to prehistoric times. The invention of the spinning wheel in the Middle Ages revolutionized the process, making it faster and more efficient. Modern spinning mills use advanced machinery to produce large quantities of yarn quickly and consistently.

Spinning Techniques: Hand Spinning vs. Machine Spinning

Hand spinning, though largely replaced by machines, is still practiced by artisans and in small-scale productions. It involves drawing out and twisting fibers by hand to create yarn. Machine spinning, on the other hand, uses mechanical devices to automate the drawing and twisting processes, significantly increasing production speed and volume.

Types of Yarns Produced

Spinning produces various types of yarns, depending on the wool’s quality and the spinning method. Woolen yarns are made from carded fibers and are typically soft and fluffy, making them ideal for warm, insulating fabrics. Worsted yarns, produced from combed fibers, are smoother and stronger, suitable for fine, durable textiles.

7. Dyeing

Natural vs. Synthetic Dyes

Dyeing wool involves coloring the fibers to produce vibrant and long-lasting hues. Natural dyes, derived from plants, minerals, and insects, have been used for centuries and are prized for their environmental friendliness and unique colors. Synthetic dyes, developed in the 19th century, offer a broader range of colors and improved colorfastness, making them popular in commercial wool processing.

Dyeing Techniques

Wool can be dyed at various stages of processing, including as raw fleece, spun yarn, or finished fabric. Common dyeing techniques include:

Batch Dyeing:

Wool is immersed in a dye bath and agitated to ensure even coloring.

Continuous Dyeing:

Wool passes through a series of dye applicators and fixers in a continuous process.

Hand Dyeing:

Artisans apply dyes manually, allowing for creative and unique color patterns.

Environmental and Health Considerations

While synthetic dyes provide vibrant colors and durability, they can have environmental and health impacts if not managed properly. The textile industry is increasingly adopting eco-friendly dyeing methods, such as using low-impact dyes, recycling dye bath water, and implementing strict waste management protocols to minimize these effects.

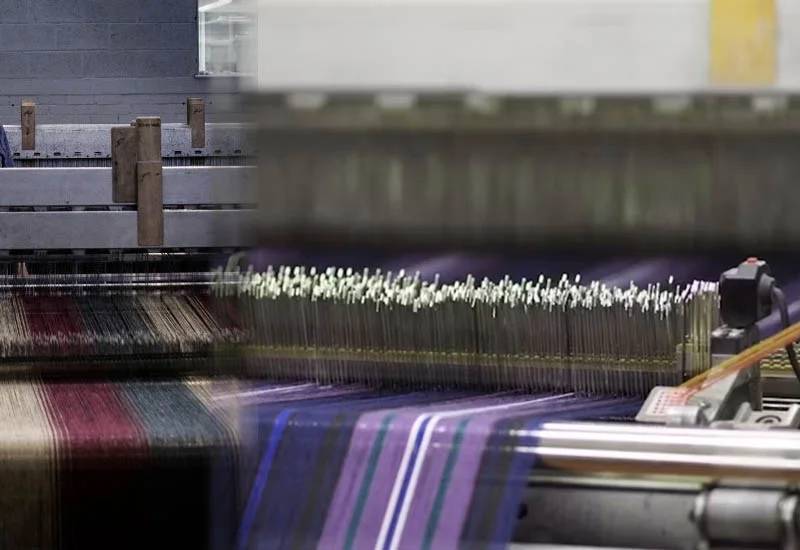

8. Weaving

Basics of Weaving

Weaving is the process of interlacing two sets of yarns—the warp and the weft—to create fabric. The warp yarns are stretched vertically on a loom, and the weft yarns are woven horizontally through them. This interlacing forms the structure of the fabric.

Types of Weaves

Different weaving patterns produce various fabric textures and properties. Common weaves include:

Plain Weave:

The simplest weave, with each weft thread passing over and under warp threads alternately.

Twill Weave:

Characterized by diagonal lines on the fabric surface, created by offsetting the interlacing pattern.

Satin Weave:

Produces a smooth, glossy surface by allowing the weft threads to float over several warp threads before interlacing.

Weaving Equipment and Technology

Modern weaving utilizes advanced looms, such as power looms and automated jacquard looms, to produce high-quality fabrics efficiently. These machines can handle complex patterns and high-speed production, meeting the demands of the global textile market.

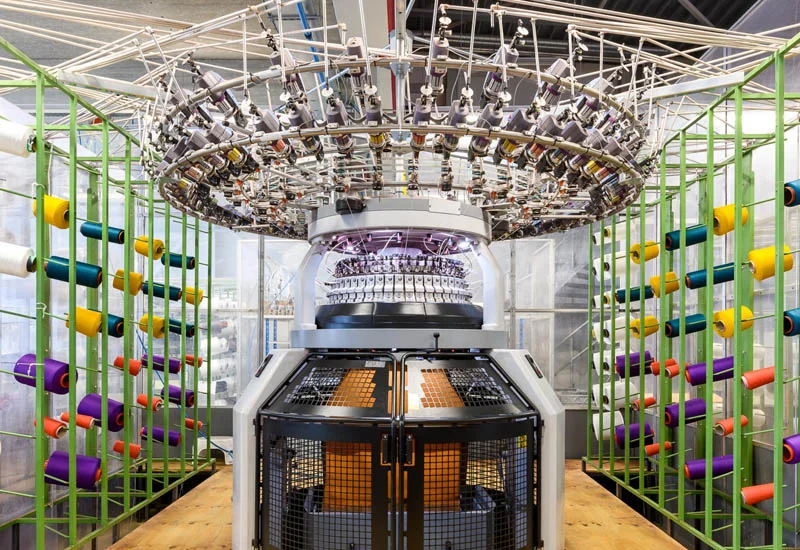

9. Knitting

Knitting Techniques

Knitting, unlike weaving, involves forming fabric by interlocking loops of yarn with needles. There are two primary knitting techniques:

Weft Knitting:

Yarns run horizontally, creating stretchy and elastic fabrics.

Warp Knitting:

Yarns run vertically, producing more stable and less stretchy fabrics.

Hand Knitting vs. Machine Knitting

Hand knitting is a traditional craft where fabrics are created manually using knitting needles. It allows for intricate patterns and personal touches. Machine knitting, however, uses automated knitting machines to produce fabrics quickly and consistently, ideal for mass production.

Types of Knitted Fabrics

Knitted fabrics vary based on the knitting technique and yarn used. Common types include:

Jersey Knit:

Soft, stretchy fabric commonly used in t-shirts and activewear.

Rib Knit:

Fabric with vertical ridges, providing excellent elasticity, is often used for cuffs and collars.

Purl Knit:

Fabric with a textured surface, offering a unique aesthetic and comfort.

10. Finishing

Importance of Finishing in Wool Fabric

Finishing is the final stage of wool processing, enhancing the fabric’s appearance, texture, and performance. This step includes various treatments to achieve desired properties such as softness, sheen, and durability.

Common Finishing Techniques

Finishing techniques vary depending on the intended use of the fabric. Common methods include:

Fulling:

Controlled shrinking to improve thickness and insulation.

Crabbing:

Setting the fabric’s dimensions and stabilizing the weave.

Decreasing:

Steaming the fabric to enhance its luster and hand feel.

Innovations in Finishing Processes

Technological advancements have introduced innovative finishing techniques, such as enzyme treatments and plasma finishing. These methods improve fabric properties while reducing environmental impact, aligning with sustainable production goals.

11. Quality Control

Quality Control Measures in Wool Processing

Quality control is essential to ensure the consistency and durability of wool fabrics. Throughout processing, various checks and tests are conducted to maintain high standards.

Testing Methods

Common testing methods include:

Micron Measurement:

Assessing fiber diameter for softness and fineness.

Tensile Strength Testing:

Ensuring the yarn’s strength and durability.

Colorfastness Testing:

Evaluating the fabric’s resistance to fading and bleeding.

Ensuring Consistency and Durability

Implementing stringent quality control measures ensures that the final wool products meet industry standards and consumer expectations. Consistency in quality helps build brand reputation and customer trust.

Which Countries Produce Wool Fabric With Good Quality?

How is wool processed into fabric? each country has its own successful experience. as users, we have more choices.

| Country | Historical Context | Types of Wool Produced | Key Regions | Quality Standards | Major Producers |

|---|---|---|---|---|---|

| Australia | Rich history since the early 19th century with the introduction of Merino sheep. | Merino, Crossbred | New South Wales, Victoria, Western Australia | Australian Wool Exchange (AWEX), National Wool Declaration (NWD) | AWN (Australian Wool Network), Fox & Lillie Rural, Michell Wool, G. Schneider Australia |

| New Zealand | Storied history linked with agricultural heritage, sheep were introduced in the early 19th century. | Strong wool (Romney, Coopworth), Merino | Canterbury, Otago, Manawatu, Wairarapa | New Zealand Wool Testing Authority (NZWTA) | Wools of New Zealand, PGG Wrightson Wool, NZ Merino, WoolWorks |

| China | Emerged as a significant player in recent decades, investing heavily in sheep farming and processing. | Merino, Coarser wool from crossbred sheep | Inner Mongolia, Xinjiang, Gansu | China Wool Textile Association (CWTA) | F and A Fabric, Ningxia Zhongyin Cashmere Company, Inner Mongolia Erdos Group |

| United Kingdom | Long history dating back to medieval times, with wool being a major export. | Merino, Bluefaced Leicester, Scottish Blackface, Romney | Scotland, Wales, Northern England | British Wool Marketing Board (BWMB) | Jamieson & Smith (Shetland Wool Brokers), Wool Board, Blacker Yarns, John Arbon Textiles |

| South Africa | The wool industry dates back to the early 19th century with the introduction of Merino sheep. | Fine Merino, Dohne Merino, South African Mutton Merino | Eastern Cape, Free State, Western Cape | South African Wool and Mohair Buyers Association (SAWAMBA), Cape Wools SA | BKB Limited |

| Argentina | Historical production is rooted in European settlement, with a focus on Merino sheep. | Merino, Corriedale | Patagonia, Buenos Aires, La Pampa | Argentine Wool Federation (FWPA) | Fuhrmann SA, Lanas Trinidad, Ovis 21 |

| Uruguay | Rich wool production history, with a strong emphasis on quality and sustainability. | Merino, Corriedale | Montevideo, Tacuarembó, Paysandú | National Secretariat of Wool (SNLA) | Central Lanera Uruguaya, Tops Fray Marcos, Lanera Piedra Alta |

| India | Wool production dates back centuries, with diverse sheep breeds across regions. | Deccani, Gaddi, Rampur Bushair | Rajasthan, Himachal Pradesh, Jammu and Kashmir | Wool Research Association (WRA), Central Sheep and Wool Research Institute (CSWRI) | Woolmark India, Vardhman Textiles, Raymond Limited |

| Turkey | Long-standing tradition in wool production, known for its diverse wool types. | Kivircik, Merino, Awassi | Anatolia, Eastern Turkey | Turkish Wool and Mohair Producers Association | Akkaraman, Sümer Holding, Altinbölme Tekstil |

| Iran | Ancient wool production traditions, with a focus on both fine and coarse wool. | Merino, Kermani, Makooei | Khorasan, Kurdistan, Fars | Iranian Wool and Mohair Association (IWMA) | Iran Merino Company, Zarrin Baf |

| France | Historical production with a reputation for high-quality wool, particularly from Merino sheep. | Merino, Prealpes du Sud | Brittany, Provence-Alpes-Côte d’Azur | French Wool Federation (Fédération Française de la Laine) | Les Toisons Bretonnes, Ardelaine, Filature Terrade |

| Italy | Known for luxurious wool products, combining tradition with modern techniques. | Merino, Sopravissana | Tuscany, Piedmont, Veneto | Italian Wool Federation (Federazione Italiana della Lana) | Loro Piana, Zegna Baruffa, Reda |

| Spain | Historical significance in wool production, particularly from Merino sheep. | Merino, Churra, Manchega | Castile and León, Extremadura | Spanish Wool Federation (Federación Española de la Lana) | Val de San Lorenzo, Hilaturas Ferre, Artesa |

| Portugal | Long history in wool production, known for its artisanal techniques. | Merino, Bordaleira | Beira Interior, Alentejo, Serra da Estrela | Portuguese Wool Association (Associação Portuguesa da Lã) | Ecolã, Burel Factory, Tinturaria de Lã |

The Purpose of Wool Fabric

Now that we know how is wool processed into fabric, let’s learn how to use wool fabric.

Insulation:

Wool is renowned for its natural insulation properties, making it ideal for use in garments, blankets, and upholstery. Wool fibers trap air, creating a layer of warmth that helps regulate body temperature in both cold and warm climates.

Moisture Management:

Wool has the ability to absorb moisture while still feeling dry to the touch, making it comfortable to wear in various weather conditions. This moisture-wicking property helps keep the wearer dry and comfortable by drawing perspiration away from the skin.

Durability:

Wool is inherently durable and resistant to wear and tear, thanks to its unique structure and natural elasticity. Wool garments and textiles are known for their longevity, making them a sustainable choice compared to synthetic alternatives.

Versatility:

Wool fabric is highly versatile and can be used in a wide range of applications, from clothing and accessories to home furnishings and industrial uses. Its versatility stems from the ability to be woven into different textures and weights, catering to diverse needs and preferences.

Comfort:

Wool fabric offers exceptional comfort due to its softness, flexibility, and breathability. It drapes well, providing a comfortable fit in clothing, and feels cozy against the skin in blankets and bedding.

Natural and Sustainable:

As a renewable and biodegradable fiber, wool is environmentally friendly compared to synthetic materials. Sheep, the source of wool, are raised sustainably in many regions, contributing to the eco-friendliness of wool production.

Aesthetic Appeal:

Wool fabric is prized for its aesthetic qualities, including its natural luster, rich colors, and texture. It lends a luxurious and timeless appeal to garments and home textiles, adding sophistication to any setting.

FAQs

What is the initial step in processing wool into fabric?

The initial step in processing wool into fabric is shearing, where wool is harvested from sheep using electric clippers or traditional hand shears. This step is crucial to obtaining raw wool for further processing.

What happens after shearing?

After shearing, the wool undergoes sorting and grading. This involves separating the fleece based on factors such as fiber diameter, length, and cleanliness. Higher-quality fleece is typically reserved for fine garments, while coarser fleece may be used for carpets or industrial purposes.

What is the next stage in wool processing?

The sorted wool is then cleaned through a process called scouring. During scouring, the wool is washed to remove grease, dirt, and other impurities. This step ensures that the wool is clean and ready for spinning.

What is spinning, and how is it done?

Spinning is the process of twisting fibers together to form yarn. In wool processing, the cleaned wool fibers are carded to align them in the same direction, and then spun into yarn using spinning machines or traditional spinning wheels. This step imparts strength and cohesion to the wool fibers, preparing them for weaving or knitting.

What happens after spinning?

After spinning, the yarn may undergo additional processing steps depending on the desired end product. This may include dyeing the yarn to add color, blending different types of wool for specific qualities, or applying special finishes for enhanced texture or performance.

Conclusion

In conclusion, understanding how wool is processed into fabric reveals intricate steps. From shearing to weaving, each stage contributes uniquely. Techniques vary across regions, but the goal remains consistent. Wool’s journey highlights craftsmanship and innovation.

Once raw fleece, now transformed into versatile textiles. Quality control ensures durability and softness. Sustainability practices enhance wool’s appeal. In essence, the journey from sheep to fabric embodies tradition and modernity.