Fabric printing has become a popular trend lately, whether for custom crafts, personalized fashion, or home décor projects. If you’ve been wondering if cotton fabric is suitable for printing, the short answer is yes!

Cotton is one of the best fabrics to work with, thanks to its smooth texture, versatility, and affordability. It holds prints beautifully, making it perfect for everything from quilts to custom T-shirts and cushion covers.

In this guide, we’ll walk you through the different printing methods for cotton, share tips to make your designs stand out, and discuss how to care for your printed fabric to keep it looking its best. Ready to unleash your creativity? Let’s dive into the world of fabric printing and see just how amazing cotton can be!

What is Fabric Printing?

Fabric printing is the process of applying designs or patterns to textiles using different techniques. It’s a popular way to create custom items, whether for clothing, home décor, or other unique creations.

Typically, this involves using ink, dye, or pigments to imprint a design onto the fabric. Methods like screen printing, digital printing, and block printing are commonly used, each providing its own distinctive look and feel for the fabric.

-

100 Cotton Solid Fabric

100 Cotton Solid Fabric -

100% Cotton 10 Meters Printed Fabric Bolt

100% Cotton 10 Meters Printed Fabric Bolt -

100% Cotton 40 Pieces 5″ Printed Green Charm Pack Quilt Fabric

100% Cotton 40 Pieces 5″ Printed Green Charm Pack Quilt Fabric -

100% Cotton Daisies on Blue Quilted Fabric By The Yard

100% Cotton Daisies on Blue Quilted Fabric By The Yard -

5″x5″ Quilting Fabric 150GSM 40Pcs 100% Cotton Charm Pack

5″x5″ Quilting Fabric 150GSM 40Pcs 100% Cotton Charm Pack -

40pieces Col-Sweet Candy Solid Colour Jelly Rolls For Quilting Fabric

40pieces Col-Sweet Candy Solid Colour Jelly Rolls For Quilting Fabric -

100% Cotton Blue Solid Color Fat Quarter

100% Cotton Blue Solid Color Fat Quarter

Can You Print on Cotton Fabric?

Absolutely! Cotton is an amazing fabric for printing, and it’s a top choice for custom designs. Its absorbent nature and smooth texture make it perfect for a variety of printing methods. Whether you’re printing a unique design on a quilt, T-shirt, or a piece of home décor, cotton absorbs inks and dyes beautifully, resulting in vibrant, crisp prints that stand the test of time.

The fabric’s ability to hold the ink ensures your design comes out clear and vivid—ideal for creating those one-of-a-kind fabric creations. Cotton works well with a variety of inks, too. Reactive dyes are a great option because they bond with the fabric fibers, ensuring a rich and long-lasting color. Pigment inks give you bold designs, while sublimation inks are used for specific methods like photo printing.

Whether you choose digital printing, screen printing, or block printing, cotton’s absorbency helps the ink sink into the fabric, keeping your designs sharp and detailed. So yes, printing on cotton is not only possible but perfect for your creative projects!

Pros and Cons of Printing on Cotton Fabric

Pros of Printing on Cotton

Versatility: Cotton is super versatile and works for almost any project. Whether you’re printing a quilt, a trendy T-shirt, or décor items like pillows and curtains, cotton can handle it all.

Comfort: Cotton’s softness and breathability make it perfect for wearables or cozy home items. After printing, the fabric remains comfortable, which is a major plus when creating things like bedding or clothing.

Eco-Friendly: Being a natural, biodegradable fabric, cotton is more eco-friendly compared to many synthetics. If sustainability matters to you, cotton is a fantastic choice for creating custom prints with a minimal environmental impact.

Ease of Use: Cotton’s smooth surface makes it easy to print on. Whether you’re a beginner or an experienced crafter, cotton’s forgiving nature ensures your designs turn out crisp and clear, no matter what printing method you use.

Cons of Printing on Cotton

Ink Absorption: Cotton is quite absorbent, which means it soaks up ink differently than other fabrics. This can lead to softer prints that might appear a little “fuzzy.” You may need to adjust your ink usage or printing method to get the sharp look you want.

Fading: Over time, especially with frequent washing or sun exposure, printed designs on cotton can fade. To combat this, make sure to use high-quality inks and follow care instructions to maintain the vibrancy of your prints.

Wrinkling: Cotton wrinkles easily, and this can impact how your design looks. If you’re making clothes or home décor items that need a crisp appearance, be prepared to press or iron your fabric before or after printing to keep everything looking sharp.

Types of Printing Techniques for Cotton Fabric

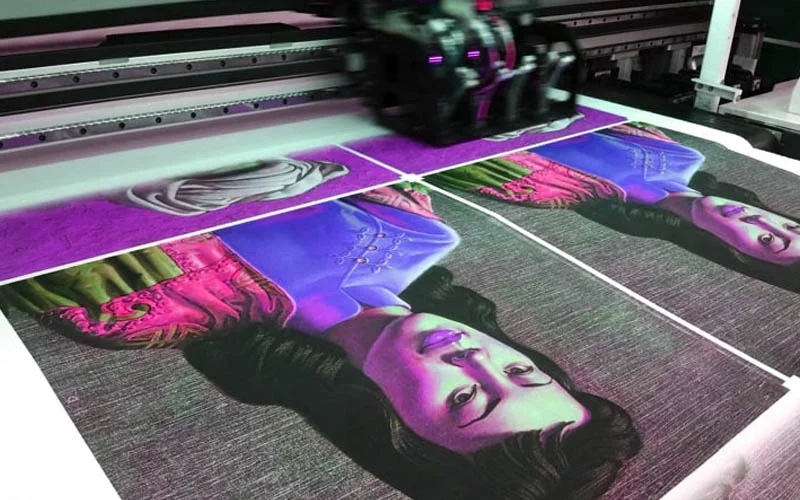

1. Digital Printing on Cotton

How It Works: Digital printing applies designs directly onto cotton fabric using inkjet or other digital printers. The printer sprays tiny droplets of ink to create detailed and colorful designs with high precision.

Pros and Cons:

- Pros:

- Excellent for intricate designs and detailed artwork.

- No setup costs, perfect for one-off projects.

- Great for custom designs.

- Cons:

- Requires specialized equipment, which can be costly.

- Ink costs can add up for larger projects.

Best For: Custom one-off designs, small batches, and detailed projects.

2. Screen Printing on Cotton

How It Works: In screen printing, ink is pushed through a mesh screen or stencil onto the fabric, creating the design. Each color requires a separate screen.

Pros and Cons:

- Pros:

- Cost-effective for large runs.

- Produces vibrant, rich colors.

- Ideal for simple designs.

- Cons:

- Time-consuming setup, especially for multi-color designs.

- Not great for intricate details.

Best For: Bulk production, T-shirts, tote bags, and simple logos or designs.

3. Sublimation Printing on Cotton

Sublimation is best for polyester or polymer-coated fabrics, as it turns ink into gas and bonds with synthetic fibers. Cotton doesn’t hold sublimation ink well.

Alternatives to Sublimation for Cotton: Use digital or heat transfer printing for better results on cotton fabric.

4. Heat Transfer Printing

How It Works: Heat transfer printing transfers a design from a special paper onto cotton fabric using heat. The design is printed on transfer paper first, then applied to fabric with heat.

Pros and Cons:

- Pros:

- Easy setup, perfect for DIY projects.

- Great for small batches.

- Produces vibrant colors.

- Cons:

- Durability can be an issue with frequent washing.

- Limited by the size of transfer paper for large designs.

Best For: DIY projects, small runs, and personal T-shirt designs.

5. Block Printing on Cotton

How It Works: Block printing involves carving a design into a wooden block, inking it, and stamping it onto fabric. It’s a traditional, hands-on method with a rustic feel.

Pros and Cons:

- Pros:

- Traditional, rustic style.

- Doesn’t require complex equipment.

- Cons:

- Time-consuming and labor-intensive.

- Results may vary, especially for beginners.

Best For: Handmade, artisanal projects like quilts or unique fabric designs.

6. Foil Printing on Cotton

How It Works: Foil printing uses adhesive to apply a metallic foil to fabric, creating a shiny and eye-catching effect.

Pros and Cons:

- Pros:

- Produces stunning metallic finishes.

- Adds a luxurious, high-end look.

- Cons:

- Requires precision when applying adhesive and foil.

- Can be difficult to work with for large designs.

Best For: High-end fashion, home décor, and accessories.

7. Lino Printing on Cotton

How It Works: Lino printing involves carving a design into a linoleum block, which is then inked and stamped onto fabric. It’s a great method for creating bold, handmade designs with texture.

Pros and Cons:

- Pros:

- Great for creating unique, hand-crafted designs.

- Cost-effective for smaller batches.

- Cons:

- Labor-intensive and requires a steady hand.

- Best for simpler designs—intricate details can be difficult to carve.

Best For: Limited edition prints, artistic projects, and small custom runs.

How to Print on Cotton Fabric?

Step 1: Prepare Your Cotton Fabric

Before you begin printing, it’s essential to prepare your fabric. This will ensure your prints come out crisp and vibrant, and your fabric lasts for years.

- Pre-wash Your Fabric: Washing removes any oils, dirt, or chemicals that might be left from manufacturing. It also prevents shrinking after you’ve printed. Be sure to wash your fabric as you would after printing to get a sense of how it will behave.

- Iron the Fabric: Wrinkles can interfere with printing, so ironing your fabric before you start is key. A smooth, flat surface helps your design stick more evenly and ensures a crisp, clean print.

Step 2: Choose the Right Printing Technique

Which one you go with depends on your project, the number of items you need, and the level of detail in your design.

- Digital Printing: Perfect for custom designs with lots of detail. This method allows you to print intricate images directly onto the fabric. It’s ideal for one-off projects or small batches. Just make sure to set your printer resolution correctly for the sharpest prints.

- Screen Printing: Best for larger runs, like T-shirts or tote bags. It involves creating a stencil of your design and pressing ink through it. While it’s fantastic for bold, simple designs, it requires more setup time and multiple screens for different colors.

- Heat Transfer Printing: A beginner-friendly method that works well for small projects. You print your design onto transfer paper, then use heat (from an iron or heat press) to transfer it to the fabric. It’s easy and works well for multi-color designs but may not last as long as other methods.

Step 3: Print Your Design

- Digital Printing:

- Set up your printer with fabric-compatible ink (like pigment or reactive dye).

- Design your image on your computer. If it includes text, flip it horizontally so it doesn’t appear backward.

- Load the fabric into the printer, making sure it’s smooth and wrinkle-free, and print the design directly onto the fabric.

- Screen Printing:

- First, create a stencil of your design on a screen (a mesh frame). You’ll need one screen per color in your design.

- Position the screen on top of the fabric, apply the ink, and use a squeegee to press the ink through. Repeat for each color.

- Heat Transfer Printing:

- Print your design onto the transfer paper. Be sure to follow the instructions on the paper for fabric type (light or dark).

- Place the transfer paper onto the fabric, print side down, and press with an iron or heat press. Let it cool before carefully peeling away the backing.

Step 4: Post-Printing Care

After printing, proper care is essential to ensure your print lasts and stays vibrant.

- Wash and Maintain: When it’s time to wash your printed fabric, follow the care instructions carefully. For most prints, wash inside out and in cold water to preserve the design. Avoid harsh detergents and air dry or tumble dry on low heat.

- Set Your Print: Depending on your method, you might need to heat-set your design. For example, with heat transfer or screen printing, use an iron to set the design in place. Follow specific instructions for the method you used to avoid smudging or fading.

Best Materials for Printing on Cotton: A Guide for Creative Projects

Fabric Types and Their Impact on Printing

The type of fabric you choose will play a significant role in how your prints turn out. Each fabric has its own texture, weight, and feel that can enhance your design in different ways.

If you’re after a heavier fabric for durability, canvas is a great choice. Its thicker texture makes it ideal for custom bags, upholstery, and other sturdy items. Canvas holds prints beautifully, and its strong weave gives designs a unique, tactile feel. Whether it’s for a tote bag or a cushion cover, canvas is perfect for bold prints and vibrant colors.

Linen is a lightweight fabric that works best for delicate, intricate prints. Its slightly rough texture gives a rustic, organic look to your designs. Linen is perfect for soft home décor items like pillow covers or curtains, and it also works for light clothing. However, its natural texture can sometimes cause designs to appear a bit softer or less detailed compared to smoother fabrics.

Organic Cotton:

For eco-conscious projects, organic cotton is a top choice. Not only is it better for the environment, but it also provides excellent print quality. The natural fibers bond well with ink, giving you sharp and vibrant designs. Plus, organic cotton is soft on the skin, making it ideal for T-shirts, baby clothes, or anything that needs to feel gentle and comfortable.

Cotton blends, like cotton-polyester mixes, strike a balance between cost and quality. These fabrics combine the softness of cotton with the durability of synthetic fibers, making them perfect for everyday wear like T-shirts or casual home décor. They take ink well but might not absorb as deeply as pure cotton, which can lead to slightly lighter or less vibrant colors.

Best Inks and Dyes for Printing on Cotton

Printing on cotton fabric can be such a rewarding experience, and choosing the right ink or dye can really make your designs pop! let’s break it down to help you choose the best one for your project.

Water-Based Inks

Water-based inks are a popular choice for cotton. They’re not just eco-friendly, but they also give you rich, vibrant colors that look great on fabric. Plus, cleaning up is a breeze—just use water, no harsh chemicals involved! These inks soak into the cotton, allowing for a soft and breathable print that keeps the fabric feeling natural.

Best For: If you’re working on soft prints, like T-shirts, baby clothes, or lightweight home décor items, water-based inks are a great fit. They keep the fabric comfortable while giving your designs that fresh, vibrant look!

Pigment vs Dye Inks

Here’s where things get a little technical. Pigment inks sit on top of the fabric, creating a layer of color. Dye inks, on the other hand, soak into the fabric fibers, offering a more deeply absorbed color. This affects not just the look of the print, but also how long it lasts.

Which Is Best for Cotton: If you’re looking for prints that will last, pigment inks are usually the better choice. They’re more resistant to fading, even after multiple washes, which means your designs stay sharp and bright for a longer time. Dye inks can create rich, deep colors, but they might fade a bit quicker, requiring more care to keep them looking fresh.

Natural Dyes vs Synthetic Inks

If you’re all about sustainability, natural dyes are a great choice. These dyes come from plants, insects, and minerals, offering an eco-friendly option that’s biodegradable and non-toxic. They give your prints a soft, earthy vibe—perfect for unique, eco-conscious projects like home décor or organic clothing.

While natural dyes are wonderful for the environment, synthetic inks are often more reliable in terms of color consistency and durability. They tend to last longer, making them a great option for projects that need bold, crisp prints that can stand up to washing and wear. For cotton, synthetic inks are generally the go-to for vibrant, long-lasting designs.

Troubleshooting Common Printing Issues on Cotton Fabric

Ink Bleeding

Ink bleeding occurs when the ink spreads out beyond the edges of your design, causing blurry or smudged prints. Cotton fabric’s absorbent nature can sometimes make this happen.

How to Prevent Ink Bleeding:

- Pre-wash your fabric: Always wash your cotton fabric before printing to remove any oils, sizing, or residue that could mess with ink absorption.

- Choose the right ink: Use inks specifically made for fabric, like water-based or pigment inks. These will stay on top of the fabric, reducing the chances of bleeding.

- Control the fabric’s moisture: Ensure your fabric is completely dry and smooth before printing. Damp fabric can cause the ink to spread.

- Print with light pressure: If you’re using screen printing, avoid pressing too hard. A lighter touch will help keep the ink where it’s supposed to be.

Fading Designs

The last thing you want after all that work is for your design to fade after just a few washes. Fading usually happens if the ink doesn’t bond properly with the fabric, or if the fabric isn’t cared for in the right way.

Tips to Keep Prints Vibrant Over Time:

- Use high-quality inks: Opt for pigment-based inks for lasting color. If you’re using water-based inks, make sure to heat-set the design for better longevity.

- Heat-set your print: After printing, use an iron to set your design. This helps lock the color in place and prevents fading.

- Wash with care: Always wash your printed cotton fabric inside out in cold water. This reduces the wear and tear on the print and helps it last longer.

- Avoid direct sunlight: Don’t let your fabric sit in direct sunlight, as it can cause the design to fade faster.

- Dry carefully: Air dry your fabric, or tumble dry on a low heat setting. High heat can weaken the print, so it’s best to keep it gentle.

Cracking and Peeling

Cracking and peeling occur when the print starts to break apart or lift off the fabric. This is especially common with heat transfer prints or thick ink layers, but don’t worry—there are ways to prevent it.

How to Avoid Cracking and Peeling:

- Let your print cure properly: Whether you’re screen printing or using digital printing, make sure the print has had enough time to cure before handling or washing. This ensures that the ink bonds properly and doesn’t peel off with use.

- Choose the right fabric for your ink: Fabrics like 100% cotton tend to hold prints better. Ensure your fabric is compatible with the type of ink or transfer method you’re using.

- Don’t use too much ink: Overloading with ink can lead to cracking. Apply a light and even layer, and avoid saturating the fabric too much.

- Heat-set carefully: If you’re using heat transfers, follow the manufacturer’s guidelines to avoid too much heat (which can cause shrinking) or too little (which can lead to peeling).

Creative Ideas for Using Printed Cotton Fabric

Home Décor Projects

Printed cotton is perfect for brightening up your home with some DIY charm. Whether you want to add a pop of color or a unique design, printed cotton fabric is your go-to material for creating personalized home décor. Here are a few ideas:

- Cushion Covers: Custom-designed cushion covers can change the entire vibe of a room. Use bold prints for a modern look or soft florals for a cozy, vintage feel.

- Table Runners: A printed cotton table runner can instantly add a touch of elegance to your dining space. Choose patterns that complement your table settings and seasonal décor.

- Curtains: Printed cotton curtains are a great way to bring color and personality into your space. Whether you’re going for something bold and dramatic or soft and airy, cotton fabric can handle any design.

- Wall Art: Yes, you can print fabric and turn it into a statement piece for your wall! Frame your favorite fabric prints or stretch them over a canvas for a unique, handmade touch.

Fashion Projects

If you’re into fashion, printing on cotton fabric opens up endless creative possibilities. You can design your own custom clothing items or accessories that stand out and reflect your personal style. Here are some ideas:

- Custom Dresses and Shirts: Why settle for ready-made clothes when you can create your own? Design custom dresses, shirts, or skirts with printed cotton fabric in your favorite patterns. Whether it’s a bold graphic or a delicate floral, your unique design will be one of a kind.

- Accessories: Printed cotton is perfect for accessories like scarves, headbands, or even bags. Create a fun and fashionable statement piece that you can wear or gift to friends and family.

DIY and Craft Projects

If you’re a DIY enthusiast or looking for a craft project to dive into, printed cotton is the perfect material for all sorts of fun creations. Here are a few projects that make the most of printed cotton fabric:

- Tote Bags: A custom-designed tote bag is not only functional but also adds a personal touch to your everyday carry. Choose a print that matches your style, or create a quirky design that makes people smile.

- Aprons: Printed cotton aprons are not only practical but can also add personality to your kitchen. Whether you’re baking, cooking, or crafting, a cute, personalized apron is a must-have.

- Small Gift Items: Print cotton fabric and turn it into handmade gifts like bookmarks, pouches, or keychains. A thoughtful, homemade gift always has a special touch.

Quilting and Patchwork

- Custom Quilts: You can even print your own fabric designs and incorporate them into your quilt. This makes your quilt even more special and one-of-a-kind!

- Unique and Personal Touch: Using different printed cotton fabrics in your quilt, you can add layers of personality and story to your work. Choose fabrics that have special meaning, whether it’s a family favorite pattern or prints that reflect a season, event, or memory.

- Mixing Prints: Don’t be afraid to mix and match various printed cotton fabrics. Combining different prints in a single quilt creates a beautiful, dynamic effect. Play with color, scale, and texture to make each block in your quilt stand out.

Conclusion

Printing on cotton fabric is a great way to add your personal touch to any project. With the right ink, fabric, and technique, you can make stunning designs that really pop. Whether you’re working on home décor, fashion, or quilting, cotton gives you endless possibilities, from digital printing to screen printing or heat transfers.

Now, it’s time to get creative! Don’t be afraid to mix up different materials and techniques to see what works best for you. Jump into your next project and let the fabric inspire you—you’ll be amazed at the beautiful designs you can create!