When you’re searching for durable gear – be it a new backpack, a reliable tent, or even a sturdy pair of shoes – Oxford fabric often comes up as a strong contender. Its reputation for toughness is well-established, but a crucial question frequently arises: Is Oxford fabric waterproof? This isn’t a simple yes or no answer, as the reality is more nuanced. We’re here to dive deep into what makes Oxford fabric water-resistant, when it truly stands up to the elements, and how to understand its protective capabilities. Let’s explore the factors that determine its waterproof performance.

What is Oxford Fabric

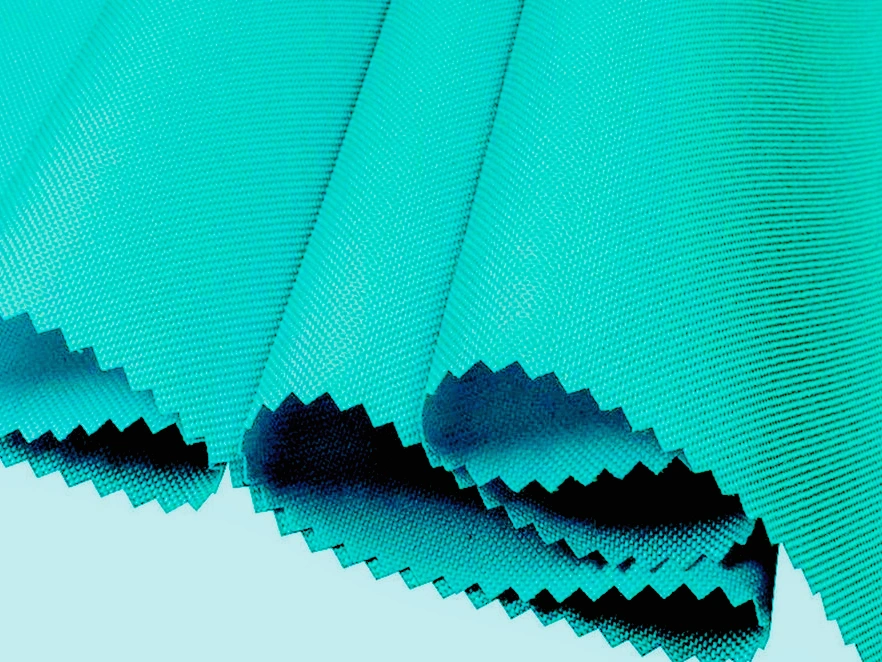

Before we can definitively answer “Is Oxford fabric waterproof?”, we first need to understand the fundamental characteristics that give this material its structure and inherent properties. Oxford fabric is renowned for its unique basket weave, where multiple warp threads are woven over one or more weft threads. This creates a distinct, slightly textured surface that is not only visually appealing but also contributes to its strength.

- The Basket Weave’s Role: The tight interlacing of threads in the basket weave inherently creates a denser fabric than a plain weave. This density provides a natural barrier against light moisture penetration. Think of it like a tightly packed wall – it’s harder for water to find a path through. However, without further treatment, this weave alone isn’t enough to withstand prolonged exposure to water or heavy downpours. Water molecules, given enough time or pressure, can eventually find their way through the minute gaps.

- Material Matters: The type of fiber used to create Oxford fabric also plays a significant role in its interaction with water.

- Cotton Oxford: Traditional Oxford fabric, especially for shirting, is made from cotton. Cotton is a natural fiber that is absorbent. While comfortable and breathable, plain cotton Oxford is generally not water-resistant and will quickly soak through in the rain.

- Polyester Oxford: This is one of the most common materials for durable Oxford fabrics. Polyester itself has low absorbency, meaning it doesn’t readily soak up water. This makes it a better starting point for water resistance compared to cotton.

- Nylon Oxford: Nylon is another synthetic fiber frequently used. It shares similar low-absorbency properties with polyester and is also known for its exceptional strength.

So, while the weave provides a good base, and synthetic materials like polyester and nylon offer inherent water-repelling qualities, these alone rarely make Oxford fabric truly waterproof. For that, we need to look at what’s added to the fabric.

Oxford Fabric Coatings and Treatments

When we ask, “Is Oxford fabric waterproof?”, the real answer often lies in the coatings and treatments applied to the fabric after weaving. These additions are what transform a water-resistant material into a truly waterproof or highly water-repellent barrier. We’ve seen these coatings make a significant difference in the performance of countless products.

Here are the primary coatings and treatments that give Oxford fabric its protective qualities:

Polyurethane (PU) Coating

This is arguably the most common and effective coating for making Oxford fabric water-resistant or waterproof.

- What it is: Polyurethane is a polymer that is applied as a thin, flexible layer to one side (typically the back) of the fabric. This coating fills the tiny gaps in the weave, creating a continuous barrier that water cannot easily penetrate.

- How it works: The PU coating acts like a shield, preventing water molecules from passing through the fabric. The thicker the coating, the higher the waterproof rating.

- Common Applications: You’ll find PU-coated Oxford fabric in a vast array of products, including backpacks, rain jackets, tents, luggage, and outdoor furniture covers. When considering “Is Oxford fabric waterproof for my new tent?”, a PU coating is what you’re looking for.

- Pros: Good balance of waterproofing, flexibility, and cost-effectiveness. It’s also relatively lightweight.

- Cons: Can degrade over time, leading to flaking or stickiness. Can reduce breathability.

Polyvinyl Chloride (PVC) Coating

For heavy-duty applications where maximum waterproofing and extreme durability are required, PVC coatings are often used.

- What it is: Polyvinyl chloride is a much thicker and more rigid polymer coating applied to the fabric.

- How it works: PVC creates an almost impenetrable barrier against water, making the fabric truly waterproof.

- Common Applications: We see PVC-coated Oxford fabric in industrial-grade tarps, heavy-duty bags, truck covers, and some very rugged outdoor gear.

- Pros: Excellent waterproofing, very durable and abrasion-resistant.

- Cons: Heavier, less flexible, and can be more prone to cracking in cold temperatures. Less environmentally friendly to produce.

Durable Water Repellent (DWR) Finish

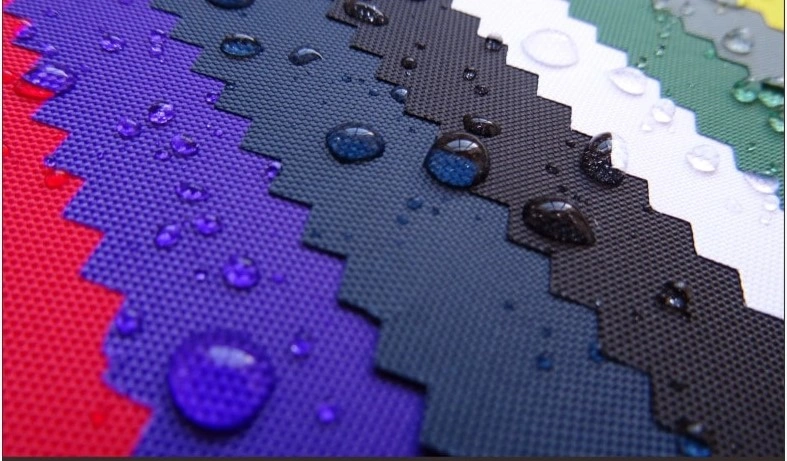

A DWR finish is different from a waterproof coating, but it’s an important part of the water resistance equation.

- What it is: DWR is a chemical treatment applied to the outer surface of the fabric. It doesn’t create a barrier, but rather changes the surface tension of the fabric fibers.

- How it works: When water hits a DWR-treated surface, it beads up and rolls off, rather than soaking into the fabric. This prevents the fabric from “wetting out” (becoming saturated), which can make it feel heavier and reduce breathability.

- Common Applications: Often used in conjunction with PU coatings on rain jackets and tents to provide an extra layer of protection and keep the fabric looking dry.

- Pros: Enhances water repellency, helps maintain breathability.

- Cons: Wears off over time with use and washing, requiring reapplication. It does not make the fabric waterproof on its own.

Other Considerations: Taped Seams and Zippers

Even with the best waterproof Oxford fabric, water can still find its way in through stitching holes and zippers. This is why truly waterproof products incorporate additional features:

- Taped Seams: For items like rain jackets or tents, seams are often sealed with waterproof tape on the inside. This prevents water from leaking through the needle holes created during sewing.

- Water-Resistant Zippers: Zippers themselves can be a weak point for water entry. Many products use water-resistant zippers (often with a PU coating or a storm flap) to prevent moisture from seeping through.

So, when assessing “Is Oxford fabric waterproof?” for a product, we need to consider not just the material and coating, but also how the entire product is constructed to keep water out.

How We Measure Protection

When manufacturers claim that Oxford fabric, or a product made from it, is waterproof, how do we quantify that claim? The answer lies in standardized tests that measure a fabric’s resistance to water pressure. The most common measurement we encounter is the hydrostatic head rating, often expressed in millimeters (mm). This tells us a lot about “Is Oxford fabric waterproof for intense conditions?”

Hydrostatic Head Rating (mm)

- What it is: This test measures the height of a column of water (in millimeters) that the fabric can withstand before water begins to penetrate.

- How it works: A piece of fabric is pulled taut under a column of water. The height of the water column is gradually increased until three drops of water are observed to pass through the fabric. That height in millimeters is the hydrostatic head rating.

- Interpretation:

- 0-1,500 mm: Generally considered not waterproof or only minimally water-resistant. Might repel light mist or very short exposure.

- 1,500 – 5,000 mm: Water-resistant to moderately waterproof. Good for light rain or short periods of moderate rain. This is a common rating for many entry-level rain jackets and some backpacks.

- 5,000 – 10,000 mm: Waterproof. Suitable for moderate to heavy rain. This is a good rating for most tents and reliable outdoor jackets.

- 10,000 – 20,000+ mm: Highly waterproof to extremely waterproof. Designed for prolonged heavy rain, wet snow, and high-pressure situations (e.g., sitting on wet ground for extended periods, or high-performance expedition gear).

Quick Reference: Hydrostatic Head Ratings

| Rating (mm) | Description | Typical Use |

|---|---|---|

| 0 – 1,500 | Minimal Water Resistance | Casual bags, windbreakers (not for rain) |

| 1,500 – 5,000 | Water-Resistant / Moderately Waterproof | Light rain jackets, daypacks, light tents |

| 5,000 – 10,000 | Waterproof | Most tents, reliable rain jackets, medium-duty backpacks |

| 10,000 – 20,000+ | Highly to Extremely Waterproof | Expedition tents, heavy-duty outerwear, dry bags |

Other Testing Standards

While hydrostatic head is the most common, other standards exist, such as:

- Spray Rating Test: Measures how well water beads up and rolls off the surface of the fabric, assessing its DWR performance.

- Rain Chamber Test: Simulates various rainfall intensities to assess a garment’s overall waterproofness, including seams and zippers.

When buying a product, we always look for specific hydrostatic head ratings and mentions of taped seams, as these provide the clearest indication of “Is Oxford fabric waterproof enough for my needs?”

Factors Affecting Waterproof Performance Over Time

Even if an Oxford fabric product is initially waterproof, its performance can degrade over time. We’ve certainly seen this with our own gear, and understanding why helps us maintain its protective qualities.

Here are the key factors that can impact how long Oxford fabric remains waterproof:

- Abrasion and Wear: Repeated rubbing, scraping, and general wear and tear can abrade the outer DWR finish and eventually damage the inner waterproof coating. This is especially true in high-stress areas like shoulder straps on a backpack or the knees of rain pants.

- Dirt and Oils: Dirt, body oils, and residues from detergents can clog the pores of the fabric and break down the DWR finish, causing water to “wet out” instead of beading up. This can make the fabric feel less breathable and eventually compromise the waterproof coating.

- UV Exposure: Prolonged exposure to ultraviolet (UV) radiation from the sun can degrade both synthetic fibers (like polyester and nylon) and their waterproof coatings, making them brittle, less effective, and prone to flaking.

- Chemical Exposure: Harsh detergents, bleaches, or other chemicals can strip DWR finishes and damage waterproof coatings. This is why specific care instructions are so important.

- Flexing and Folding: Constant flexing and folding, especially in cold temperatures, can cause microscopic cracks in PU or PVC coatings over time, creating pathways for water.

- Manufacturing Defects: While less common with reputable brands, sometimes a product may have a manufacturing defect, such as an improperly sealed seam or a weak point in the coating, that compromises its waterproofness from the start.

Understanding these factors allows us to take better care of our Oxford fabric items and take steps to restore their waterproof qualities when needed.

Maintaining and Restoring Waterproofing in Oxford Fabric

Just because an Oxford fabric item starts to lose its waterproof prowess doesn’t mean it’s time for the trash. We’ve found that with proper care and occasional re-treatment, we can significantly extend the life of our gear.

Here are our top tips for maintaining and restoring the waterproof performance of Oxford fabric:

- Regular Cleaning:

- Spot Clean First: For minor dirt, gently wipe the area with a damp cloth and mild soap.

- Proper Washing (if applicable): If the item needs a full wash (check care label!), use a technical wash designed for waterproof fabrics (e.g., Nikwax Tech Wash or Grangers Performance Wash). Avoid standard detergents, as they can leave residues that hinder water repellency. Always use cold water and a gentle cycle.

- Reactivating DWR:

- After cleaning, the DWR finish on the fabric surface might be “clogged” or flattened. Sometimes, a gentle tumble dry on low heat (if the label allows) can reactivate the DWR. The heat helps to realign the water-repellent polymers on the surface.

- Reapplying DWR:

- When water no longer beads up effectively, it’s time to reapply a DWR treatment. These come in spray-on or wash-in formulas.

- Spray-on: Apply evenly to a clean, damp, or dry fabric surface. Good for spot treating or items that can’t be washed.

- Wash-in: Add to the washing machine with the clean item. This provides a more even coating but can reduce breathability if applied to inner liners.

- Follow the product instructions carefully!

- Repairing Coatings:

- For minor flaking or peeling of internal PU coatings, there are specialized fabric sealants and repair kits available that can help patch small areas. For extensive damage, however, repair might be impractical.

- Proper Storage:

- Store Oxford fabric items in a cool, dry place away from direct sunlight. Ensure they are completely dry before storing to prevent mildew growth and coating degradation. Avoid excessive folding or crushing, which can stress coatings.

By taking these proactive steps, we can ensure our Oxford fabric gear continues to provide the waterproof protection we rely on, extending its lifespan and maximizing our investment.

Conclusion

True waterproofness depends on its unique weave, the type of fiber used and, crucially, the coating and treatment process. Ordinary uncoated cotton Oxford cloth is not waterproof or has very limited waterproof properties. For more information on fabrics, please contact us.