Blended fabrics are behind some of the most versatile textiles you see today. By combining natural fibers like cotton with synthetics like polyester, these fabrics deliver the best of both worlds—durability and comfort.

Whether you’re crafting a cozy quilt or sewing up a stylish shirt, blending fibers enhances your project with strength, softness, and flexibility. These fabrics are a go-to choice in modern design because they balance the strengths and weaknesses of both materials.

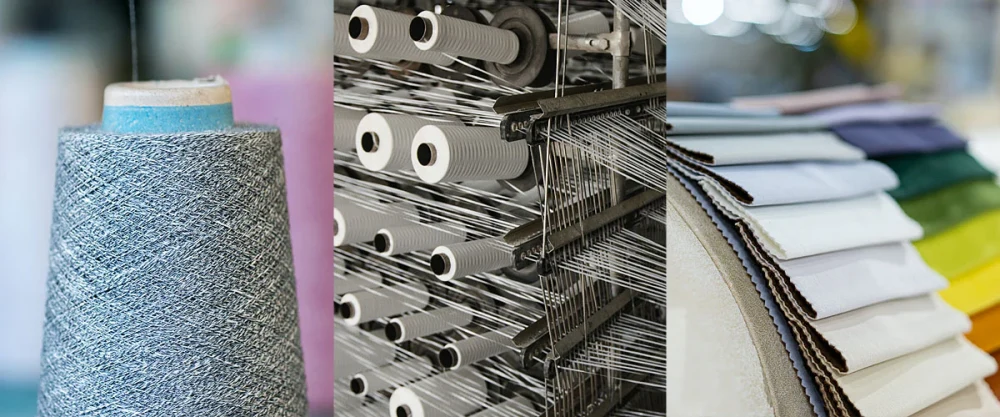

Curious about how these amazing blends are created? Dive into our article to discover the step-by-step process of making blended fabrics and how they’re transforming the textile industry.

What Are Blended Fabrics?

Blended fabrics are all about combining different fibers to create the perfect balance of strength, comfort, and performance. Think of it like a recipe—each fiber brings something unique, and when mixed, they create a fabric that’s better than each material alone.

For example, cotton and polyester blends are breathable and wrinkle-resistant, perfect for easy-care clothing. Wool and nylon blends provide warmth and durability, making them ideal for outerwear.

Why Mix Fibers?

It’s all about improving performance. Natural fibers like cotton or wool are soft and breathable, but they might not be as durable or wrinkle-resistant. By blending them with synthetics like polyester or nylon, you get the best of both worlds—comfort and longevity.

Common Fiber Combinations

- Polyester-Cotton: This blend is the ultimate go-to for durability and breathability. It’s perfect for things like shirts, sheets, and quilts because it resists wrinkles and holds up over time without sacrificing comfort.

- Wool-Nylon: If you’re after warmth with some serious durability, wool-nylon blends are the way to go. You get the cozy warmth of wool with the added strength of nylon, making it perfect for outerwear or sweaters that need to stand the test of time.

- Linen-Silk: Looking for luxury? This combination brings together the soft, smooth texture of silk with the crisp, breathable nature of linen. It’s a dreamy option for high-end garments like blouses and dresses or special home décor like cushions.

- Rayon-Spandex: For comfort and flexibility, rayon-spandex blends are a favorite. The rayon gives it a soft, smooth feel, while the spandex provides the stretch, making it a go-to for activewear or anything that needs to move with you.

How Are Blended Fabrics Made?

1. Fiber Selection: Choosing the Right Fibers for Blending

Fiber Options

Natural fibers like cotton, wool, linen, and silk are your comfort go-tos. They’re breathable and soft, making them perfect for everything from quilts to clothing. They feel amazing, but they can sometimes be a little less durable, which is why mixing them with synthetics can make a big difference.

Synthetic fibers like polyester, nylon, acrylic, and spandex are strong, flexible, and moisture-wicking. They add durability and stretch, making them ideal for things like activewear or outerwear. When blended with natural fibers, they give you a boost in performance without sacrificing comfort.

Blending Goals

- Softness: If you’re after that soft, comfy feel, blending natural fibers like cotton or wool with a synthetic like polyester helps soften the rougher synthetics. This makes for a cozy, everyday fabric that you’ll love.

- Durability: Natural fibers, while wonderful, can wear out over time. By blending them with durable synthetics like polyester or nylon, you get a fabric that’s strong enough for heavy use—perfect for upholstery or outerwear.

- Stretch: Need your fabric to have some give? Throw in some spandex or Lycra with cotton or wool. This adds the stretch you need, making it ideal for activewear or garments that move with you.

- Moisture-wicking: If breathability is a top priority, a polyester-cotton blend is your best friend. It wicks moisture away, keeping you cool and dry—great for active clothing or anything that needs to breathe.

- Sustainability: Many brands are offering eco-friendly fibers like organic cotton or recycled polyester. Blending these fibers lets you create sustainable fabrics that are both functional and better for the planet.

2. The Fiber Preparation Process

Carding:

This is the first step in preparing your fibers. The fibers are cleaned and opened up to remove any tangles or impurities. Think of it like getting the ingredients ready before baking a cake—you want everything in the right condition for the next steps.

Combing:

After carding, the fibers are combed to remove any short or broken fibers. This ensures that only the long, strong fibers stay in the mix, which gives your fabric a smoother, more consistent finish.

Opening & Laying:

Once the fibers are ready, they’re mixed and laid out for consistency. This step is about making sure that every fiber is evenly distributed, giving your fabric a solid, uniform structure.

When it comes to blending techniques, there are two main approaches:

Intimate Blending:

This technique ensures the fibers are mixed so well that you can’t tell where one ends and the other begins. The fibers intermingle to create a seamless fabric with a balanced blend of qualities. This is the kind of blending you see in fabrics like cotton-polyester blends, which combine the softness of cotton with the durability of polyester.

Cross-Lapping:

In this method, fibers are spread out at an angle, which helps them distribute evenly and creates a fabric that’s strong and consistent. It’s often used when you need more structure, like in outerwear or upholstery fabrics.

3. Spinning Techniques: Turning Fibers into Yarn

Spinning is the process that turns fibers into yarn, and that yarn will later be woven or knitted into fabric. This step is key in determining the fabric’s strength, texture, and how it performs, whether it’s for clothing, upholstery, or other uses.

By adjusting the spinning machines, you can control how thick or thin the yarn is, allowing you to create fine, delicate threads for lightweight fabrics or thicker, textured yarns for heavier materials.

Ring Spinning:

This classic method has stood the test of time. It creates smooth, strong yarns that are perfect for high-quality fabrics. Although it’s a slower process, it’s worth it when you need durable, long-lasting yarn. It’s the go-to for everything from cozy bedding to premium quilts!

Open-End Spinning:

If you need something quicker and bulkier, this one’s for you. Open-end spinning produces thicker, coarser yarns, making it ideal for more casual, durable fabrics like denim or upholstery, where speed and bulk are more important than the perfect finish.

Air-Jet Spinning:

A faster, high-tech method that uses air to twist the fibers, air-jet spinning creates lighter, fluffier yarns. The result is bulkier but still soft, making it perfect for fabrics that need to be airy and comfortable—think light shirts or scarves.

Core-Spun Yarn:

This technique wraps a stretchy core material, like spandex, with other fibers like cotton or wool. The result is a flexible, durable yarn with the comfort of the outer fibers and the stretchiness of the core. It’s great for making fabrics that need a little give, like activewear or stretchy upholstery.

Twist and Twist Variation:

The amount of twist in your yarn plays a huge role in its texture, strength, and even its look. Want a tighter, stronger yarn? Use more twist. Looking for something softer and fluffier? Less twist is the way to go. It’s all about balancing the twist to suit your project.

Microfiber Spinning:

For ultra-soft, fine fibers, microfiber spinning is your best bet. It creates incredibly smooth, silky yarns that are perfect for luxurious fabrics. Think super-soft bedding or plush garments—anything that feels soft and indulgent to the touch.

4. Weaving and Knitting: Transforming Yarn into Fabric

Weaving and knitting are two essential techniques used to create the fabric we all love. While weaving gives us structured, strong materials, knitting offers flexibility and comfort. Both methods form the foundation of nearly every textile used in fashion, home decor, and beyond. Let’s break down these two methods and explore how they work to give you the fabric that’s just right for your projects.

Weaving Techniques:

Plain Weave:

This is the simplest and most common weaving technique. The warp (vertical) and weft (horizontal) yarns are woven in a basic over-under pattern. The result is a strong and durable fabric that’s perfect for everyday items like shirts, bedding, and even canvas. It’s reliable, easy to work with, and forms the backbone of many fabrics you’ll encounter.

Twill Weave:

Twill weave is known for its distinctive diagonal pattern, which you can spot in fabrics like denim. This weave creates a fabric that’s sturdy and resistant to wrinkles. It’s often used in things like jeans, jackets, and upholstery because of its durability and slightly textured feel.

Satin Weave:

If you’ve ever felt satin, you know how luxurious it feels. The satin weave creates a smooth, shiny surface by weaving the warp threads over several weft threads at a time. This technique is what gives fabrics like silk, satin, and charmeuse their soft and glossy finish, making them perfect for elegant garments and high-end home decor.

Jacquard Weave:

Jacquard weaving is where things get intricate. With this technique, patterns and designs are woven directly into the fabric, allowing for beautiful floral prints, geometric designs, or even custom logos. You’ll often see jacquard used in upholstery, high-end fashion, or statement pieces where the texture and design are just as important as the fabric itself.

Knitting Techniques:

Weft Knitting:

This technique involves creating horizontal loops, and it’s what gives us some of the softest, most flexible fabrics. Think t-shirts, sweaters, and scarves—those comfy clothes are often made from weft-knitted fabrics. The loops run across the width of the fabric, giving it lots of stretch and movement, which is perfect for casual wear.

Warp Knitting:

In warp knitting, the loops run vertically, which creates a fabric that’s more stable and stretchy. This technique is great for fabrics like activewear, leggings, or swimwear. It allows for a snug fit while still giving the material enough stretch to move with you, making it ideal for sportswear or anything that requires a bit of flexibility.

Circular Knitting:

Circular knitting creates fabric in continuous tubes, making it a go-to technique for items like hosiery, socks, and seamless garments. By knitting in a continuous loop, the fabric doesn’t have seams, which means more comfort and fewer places for the fabric to stretch out or wear down.

Ribbed Knits:

Ribbed knitting creates a stretchy fabric with alternating raised and recessed sections. This structure makes it perfect for things like cuffs, collars, and even sweaters. The stretchiness and texture give ribbed fabrics a snug fit and the ability to expand, which is why they’re often used in parts of garments that need to fit comfortably around the body.

5. Dyeing and Finishing

Dyeing and finishing are essential steps in transforming fabric into something ready for all kinds of projects, from clothing to home decor. These treatments don’t just enhance the fabric’s appearance—they can also boost its performance, durability, and feel. Let’s explore some of the most common techniques that can elevate your fabric from basic to beautiful, with a few functional perks along the way.

Brushing:

Brushing is a great way to soften fabric, giving it that cozy, inviting feel. It’s often used on fabrics like flannel, where the goal is to create that soft, fuzzy texture you love to snuggle into. By raising the fibers on the fabric’s surface, brushing traps air, which helps retain warmth. Perfect for those chilly nights, don’t you think?

Calendering:

If you’re a fan of smooth, shiny finishes, calendering is the treatment for you. This process uses heated rollers to smooth out the fabric and add a sleek, polished look. It’s commonly applied to fabrics like cotton and polyester, giving them that crisp, high-end finish you often see in formalwear or home textiles. It’s all about the luxe factor!

Sanforizing:

We’ve all been there—your favorite cotton shirt shrinks in the wash, right? That’s where sanforizing comes in. This treatment pre-shrinks cotton fabric before it even hits store shelves, helping to prevent any unwanted shrinkage after you wash it. It’s a game-changer, ensuring your clothes stay true to size and that your fabric keeps its shape.

Dyeing and Printing:

Dyeing and printing are the magic behind vibrant colors and eye-catching patterns. Whether you’re after a rich, bold hue or a playful print, these techniques bring fabric to life. Dyeing involves soaking the fabric in color, while printing adds intricate patterns to the surface, offering endless opportunities to get creative with your designs.

Waterproofing:

Waterproofing is what keeps you dry when the weather’s not on your side. This treatment applies a water-repellent finish to the fabric, so rain or spills won’t soak through. It’s a must-have for outdoor gear, rain jackets, and anything else that needs to keep you dry—perfect for those rainy days or unpredictable weather.

Wrinkle Resistance:

Wrinkle resistance is a blessing for anyone who’s tired of ironing. Fabrics treated with this finish resist creasing, so they stay smooth and fresh without much effort. Ideal for office wear, bedding, or travel clothing, this treatment keeps your fabric looking neat and polished, even after being tossed in the laundry basket.

Antimicrobial Treatments:

Antimicrobial treatments are a lifesaver for fabrics that see a lot of wear, like workout gear or bedding. This treatment helps prevent the growth of bacteria and odors, keeping your fabric fresher for longer. No more worrying about unpleasant smells after a workout or a long day—your fabric stays fresh and clean.

Fire Retardant Treatments:

Fire retardant treatments are essential for fabrics that need to meet safety standards, such as uniforms, upholstery, or children’s sleepwear. These treatments make the fabric less likely to catch fire, offering extra protection where it’s most needed. It’s one of those features that may not be top of mind, but it’s crucial for ensuring safety and peace of mind.

6. Quality Control: Ensuring the Fabric’s Durability and Usability

It’s all about testing fabric at every stage—from production to the final product—so it meets high standards for durability, comfort, and overall performance. Let’s dive into some of the key tests that ensure your fabric does what it’s supposed to do.

Strength Testing:

Strength testing is all about making sure your fabric can take the wear and tear of everyday life. Whether you’re making a quilt or sewing a shirt, this test checks that the fabric won’t tear or degrade over time. If your fabric doesn’t pass the test, it could start falling apart quicker than you’d like. This ensures your fabric stays strong through daily use.

Colorfastness Testing:

We’ve all had that favorite shirt or quilt fade after a few washes, right? Colorfastness testing prevents that! It makes sure the colors won’t bleed or fade, even after multiple washes or exposure to sunlight. This is especially important for fabrics you want to keep looking fresh, whether it’s your favorite quilt or clothes. Who wants their bright fabrics to lose that pop?

Shrinkage Testing:

There’s nothing worse than a fabric that shrinks way more than you expected after washing. Shrinkage testing ensures the fabric stays true to its size, so you don’t end up with something too small after the first wash. This is important for clothing, upholstery, or any project where the fabric’s size matters. The goal is to keep your fabric in shape even after several washes.

Texture & Comfort:

Let’s face it—comfort matters! Whether it’s for a quilt or a shirt, texture testing ensures the fabric feels good against your skin. This test makes sure your fabric is soft and comfy, and not scratchy or irritating. After all, you want your fabric to feel just as good as it looks, right?

Washability Testing:

Washability testing makes sure your fabric holds up after frequent washing. This test checks that the fabric keeps its texture, color, and shape, even after several washes. Whether it’s a kitchen towel or your favorite shirt, you want it to stay looking fresh and feeling good, no matter how many times it’s been through the laundry.

Conclusion

Blended fabrics are a great choice for any project, offering the perfect mix of natural softness and breathability with the strength and durability of synthetics. When you understand how these fabrics are made, it’s easier to appreciate the care and craftsmanship that goes into them.

Whether you’re making a cozy quilt or a stylish garment, blended fabrics provide versatility, durability, and comfort. Plus, there are so many combinations to try, giving you endless creative possibilities.

So why not experiment with some blended fabrics in your next project? They’re practical, stylish, and built to perform. Don’t be afraid to mix and match different fabric types to see how they can elevate your work. For top-quality quilting fabrics, be sure to check out F&A Fabric for your next crafting adventure!